International Code Requirements 2017 For Commercial Glazing Systems

Courtesy of the American Architectural Manufacturers Association

The family of I-codes published by the International Code Council (ICC) is the most widely used in the history of U.S. construction codes. Townhouses, condominiums more than four stories high, and apartment buildings, hotels and motels are considered commercial buildings in these codes. The requirements for commercial buildings are set forth in the International Building Code (IBC), the International Existing Building Code (IEBC) and the International Energy Conservation Code (IECC).

This article summarizes the major requirements for glazed assemblies, doors, skylights and other fenestration products in commercial buildings in the 2015 edition of the International Codes (I-codes).

Many jurisdictions have their own versions of particular codes. It is imperative that the code user verify the edition of the code being used, as well as applicable local amendments, in any EDITIONspecific jurisdiction prior to beginning a project there.

The following discussion of the 2015 I-codes requirements for commercial buildings emphasizes differences between the 2015 and 2012 editions. The reader is encouraged to: first, verify the edition and any amendments adopted by a particular jurisdiction; and second, consult the relevant edition of the I-codes with subsequent local amendments for complete information prior to beginning a project.

The ICC website offers updated information on which I-code editions are in effect in each state, as well as in various cities and counties.

Some jurisdiction-specific versions of the International Codes can also be obtained from the ICC, while others must be obtained directly from that particular jurisdiction.

Recent changes

There are several significant changes between the 2012 and 2015 editions of the International Codes that relate to fenestration products in commercial buildings. These changes include:

- Requirements for tornado shelters in public schools have been added to the 2015 IBC.

- UA (Area weighted average U-factor) trade-off provisions for commercial building envelopes were added to the IECC.

- Allowances for sidelighting to be used to meet mandatory daylighting requirements, as well as toplighting, have been added to the IECC.

- Maximum Prescriptive Solar Heat Gain Coefficient (SHGC) for commercial fenestration was changed. It is now to be determined based upon orientation of the fenestration, as well as the building climate zone, in the IECC.

- An exception to meeting Emergency Escape and Rescue (EERO) size requirements for replacement windows that meet other specific criteria was added to the IEBC.

- Provisions requiring the installation of window opening control devices (WOCDs) on replacement windows in locations where they would be required in new construction were added to the IEBC.

I-Code Adoption

According to the ICC website, as of fall 2016:

- The International Building Code (IBC) is used in 50 states and 4 U.S territories.

- The International Residential Code (IRC) is used in 49 states and 3 U.S. territories.

- The International Energy Conservation Code (IECC) is used in 47 states and 2 U.S. territories.

Adoption and use of the I-codes by foreign entities continues to increase. For example:

- All or portions of the IBC (in English or Spanish) are being used in the Caribbean, Haiti, Jamaica, Trinidad, Tobago, Colombia, Honduras, the country of Georgia, Abu Dhabi, Saudi Arabia and Afghanistan.

- All or portions of the IRC (in English or Spanish) are being used in Haiti, Jamaica, Trinidad, Tobago, Mexico and Abu Dhabi.

- All or portions of the IECC (in English or Spanish) are being used in the Caribbean, Jamaica, Mexico and Abu Dhabi.

With regards to energy conservation, a similar pattern is evident:

- The same number of states are enforcing the 2012 IECC as are enforcing the 2009 edition (18 states each).

- An earlier edition of the IECC is being enforced in three states.

- A locally developed energy conservation code that has been coordinated with the IECC is being enforced by one state (California).

- Only three states (Indiana, Mississippi and South Dakota) are not enforcing any energy conservation code at all.

Testing and labeling of windows, doors and skylights

Exterior windows and doors are covered in Section 1709.5.1 of the 2015 IBC. This section requires windows and sliding doors to be tested and labeled in accordance with AAMA/WDMA/CSA 101/I.S.2/A440-11, North American Fenestration Standard/Specification for windows, doors and skylights, also known as NAFS-11. The standard was developed jointly by the American Architectural Manufacturers Association, the Window & Door Manufacturers Association, and the Canadian Standards Association. (The complete document and more information are available from all three organizations.)

The 2011 edition of the joint standard applies to windows and sliding doors in both the 2012 and 2015 IBC. Other types of fenestration assemblies not included within the scope of NAFS-11, including curtain wall and storefront, are addressed in Section 1709.5.2 of the 2015 IBC. These assemblies are to be tested to 1.5 times Allowable Stress Design load in accordance with ASTM E330-02, and the glass is to be designed in accordance with ASTM E1300-12AE01.

Exterior swinging doors can be tested and labeled in accordance with NAFS-11 or tested to 1.5 times Allowable Stress Design load in accordance with ASTM E330-02. The 2015 IBC also permits garage doors to be tested to ANSI/DASMA 108-12 in lieu of ASTM E330.

NAFS-11 contains provisions for some types of exterior swinging doors. AAMA has a program to certify these types of products for compliance with NAFS-11. This program depends upon testing of each proposed door assembly, rather than the component based approach offered by ANSI A250.13 and other related standards.

Unit skylights are also required to be tested and labeled in accordance with NAFS-11 by the 2015 IBC. Unit skylights are factory manufactured fenestration assemblies intended to be installed in a single roof opening without intermediate framing members. Tubular Daylighting Devices (TDDs) are included within the definition of unit skylights in the 2015 IBC.

The requirements for skylights and sloped glazing are in Section 2405 of the 2015 IBC. Section 2405.5 permits unit skylights to be evaluated for different positive and negative design pressures, which is unique to unit skylights. Skylights are subject to snow load, as well as wind and dead load. The combination of these loads will often result in varying required ratings for positive and negative pressures on unit skylights.

The 2015 IBC requires exterior wall cladding systems, including curtain wall, storefront and punched openings, in high wind areas to be subject to special inspections. The high wind areas are determined by the exposure category of the building. If the building is in Exposure Category B (surrounded by low- to mid-rise buildings) then special inspection is required if the Allowable Stress Design wind speed is 120 mph or greater (Ultimate Design wind speed is 155 mph or greater). Exposure Category C (open prairies) or D (near large bodies of water) buildings require special inspection if the Allowable Stress Design wind speed is 110 mph or greater (Ultimate Design wind speed is 142 mph or greater).

As a general rule, wind speeds high enough to require special inspections occur primarily along the Eastern, Alaskan and Gulf Coasts. There are a few isolated pockets of high wind speed areas in certain mountainous regions of the United States that may also experience wind speeds this great. However, requirements for special inspection of exterior wall cladding systems do not apply throughout most of the United States.

When special inspections are indicated, they are only required for the part of the system design that requires a registered design professional. So, for example, if a registered design professional is required for a curtain wall system, the special inspection would only be for the structural components (framing members, anchorage, joinery, etc.)

Design loads

Provisions for design loads are set forth in Chapter 16 of the 2015 IBC. The design loads of concern for vertical glazing are design wind load and impact resistance. Skylights and sloped glazing are also subject to snow load and dead load.

Wind loads

The design wind pressure for components of the building envelope are to be calculated by the engineer of record for the project. The calculations are to be based on the design wind speed of the specific location where construction is to take place, the mean height of the building and its exposure.

There are significant changes to the design wind load requirements for fenestration between the 2009 and 2012 editions of the IBC. This is due to significant changes to the wind load provision of ASCE 7 between the 2005 and 2010 edition.

The design wind load provisions of the 2005 and earlier editions of ASCE 7 were based upon Allowable Stress Design of building components. The intent of this method was to provide loads to which the building components had a fairly high likelihood of being exposed during the service life of the building. The building components were then designed to remain serviceable (i.e. not require replacement) when subjected to that load.

The 2010 edition of ASCE 7 provides design wind load provisions that are based upon strength design of building components. This method provides loads that have a lower likelihood of occurring during the service life of the building. The building components are then designed not to fail (rupture) when subjected to that load.

This change in methodology results in higher design wind speeds and pressures when strength design loads are calculated. At first glance, this might give the appearance of requiring higher Design Pressure (DP) ratings for exterior windows, doors and skylights. However, the 2012 and 2015 IBC contain provisions to multiply this higher load by a factor of 0.6 for the purpose of conversion to the more traditional method of determining the design wind pressure based upon Allowable Stress Design.

It is very important that the builder, code official, manufacturer and anyone else involved in choosing or approving the windows, doors or skylights for a particular application understand that the higher design wind pressure provided by the 2012 and 2015 IBC must be multiplied by this 0.6 conversion factor for the purposes of comparison to the DP rating of the fenestration product. In most, but not all, cases this conversion results in required DP ratings for fenestration that are roughly comparable to the more traditionally determined values. AAMA, WDMA, FMA and DASMA published a Technical Bulletin (TB-11-1) on this topic, which may be downloaded from the AAMA website at aamanet.org.

ASCE 7-10 provides three design wind speed maps, based upon the assigned risk category of the building being designed:

- Category I. Low risk to human life, such as barns and storage facilities

- Category II. Moderate hazard to human life (most buildings fall within this category)

- Category III. High threat to human life and essential facilities. High threat buildings include assembly or education buildings designed to house groups of 250 or more people, some medical care facilities and any other buildings designed to house 5,000 people or more. Essential facilities include occupancies such as hospitals and police and fire stations, which are essential during emergency response situations.

The new maps result in higher design wind loads for buildings of moderate hazard to human life than for those of lower hazard. The highest design wind loads are given by the third map for buildings of high hazard to human life and essential facilities. Previous editions of ASCE 7 and the IBC also required these types of buildings to be designed to higher design loads, but the actual increase was applied in a different manner.

Dead loads. The provisions for dead load in Section 1606 of the 2012 IBC are also based on ASCE 7-10. There are no significant changes to the dead load requirements for fenestration between the 2012 and 2015 editions of the IBC.

Impact resistance. Section 1609.1.2 of the 2015 IBC outlines the locations where impact-resistant products are required. All exterior openings in wind-borne debris areas are required to be impact resistant in the 2015 IBC.

Determination of wind-borne debris areas in the 2015 IBC are similar to those given in ASCE 7-10 and are primarily defined by design wind speed. Since three different design wind speed maps are given in the 2015 IBC, it means some areas may be considered wind-borne debris areas for buildings such as essential facilities, but not for buildings whose collapse is considered to be of moderate or low threat to human life. In other words, in some parts of the country, impact-resistant openings will be required for hospitals, police and fire stations, but not for office buildings, retail stores or storage facilities. Those selling fenestration products in these areas need to be aware of this distinction and how it applies to their market.

Products that need to meet impact resistance requirements must be tested to one of a few different sets of standards. One option is testing in accordance with ASTM E1886-05 and ASTM E1996-2012A, which must be used together. The 2015 IBC also permits the use of “other approved tests.” This may include Miami-Dade County test protocols, if approved by the authority having jurisdiction.

Energy

Requirements for energy performance in both residential and commercial buildings are spelled out in the International Energy Conservation Code (IECC). Commercial buildings that comply with ASHRAE 90.1-13 are also considered to be in compliance with the 2015 IECC.

The 2015 IECC and ASHRAE 90.1-13 have similar formats. They both address the building envelope, mechanical systems of the building, lighting and hot water systems. Although the specific requirements for each of these systems differ between the two standards, they are considered to be very close with regards to the actual anticipated energy use of a commercial building built under either standard.

The 2015 IECC has two compliance paths for commercial construction. One available path of compliance is the Prescriptive Path. The second is the Total Building Performance Path.

The Prescriptive Path is the simplest to use. It provides one set of energy efficiency requirements for each component of the building envelope. With regards to fenestration, it establishes maximum permitted U-factors and Solar Heat Gain Coefficients (SHGC). U-factor is to be determined in accordance with NFRC 100-09 or by use of a default table in the 2015 IECC. Similarly, the SHGC of the fenestration is to be determined in accordance with NFRC 200-09 or by use of a default table in the 2015 IECC.

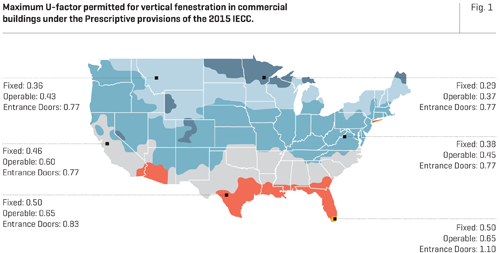

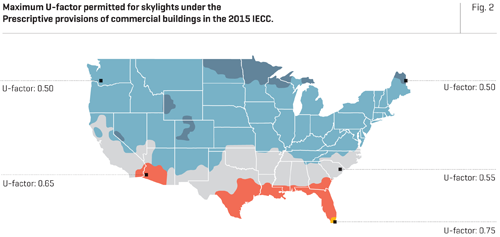

The maximum Prescriptive Ufactors for vertical fenestration and skylights in commercial buildings did not change between the 2012 and 2015 IECC. The maximum U-factors for fenestration are based upon whether it is fixed, operable, or an entrance door. Previous to the 2012 edition, the IECC contained separate Prescriptive U-factor provisions for metal and nonmetal framed windows and doors other than the main entrance door in commercial buildings. This distinction does not occur in the 2015 IECC. The 2015 IECC maximum Prescriptive Ufactors are given in Fig. 1 and Fig. 2.

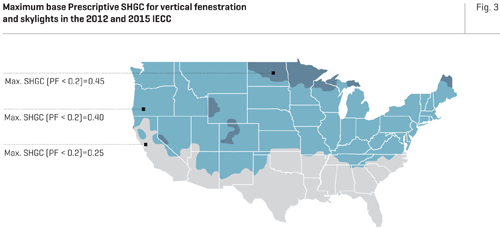

The 2012 and 2015 IECC also limit the maximum Prescriptive SHGC of fenestration in commercial buildings in most climate zones. The 2012 IECC establishes a base maximum SHGC. It is to be used if there are either no overhanging projections over the fenestration or the width of any overhang is less than one fifth of the height of the fenestration from its sill to the underside of the overhanging projection. In this case, the fenestration is considered to have a Projection Factor (PF) of < 0.20 (PF = width of projection/height of fenestration from sill of fenestration to underside of projection).

The 2015 IECC maintains the same base Prescriptive SHGC for fenestration oriented to the south, or within 45 degrees of true east or west. The maximum base Prescriptive SHGC permitted for fenestration with PF < 0.20 in the 2012 and for south, east or west oriented fenestration with PF < 0.20 in the 2015 IECC is given in Fig. 3.

Both the 2012 and 2015 editions of the IECC provide variations of the maximum permitted Prescriptive SHGC based upon both the presence and width of overhanging projections, and the orientation of the fenestration itself. The maximum Prescriptive SHGC is permitted to be increased if a permanent overhang of sufficient width is provided. The width must be at least 1/5 of the height from the fenestration sill to the underside of the overhang (PF > 0.20).

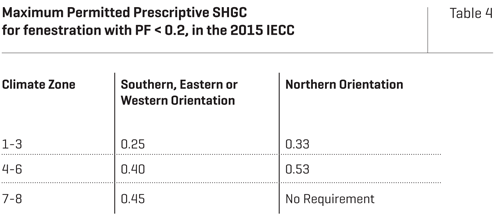

In both the 2012 and 2015 IECC, the increase to the maximum Prescriptive SHGC permitted is dependent upon the orientation of the glazing. The increase in maximum Prescriptive SHGC permitted for shaded glazing oriented to the north is less than for the other three orientations because it does not receive as much benefit from shading as the other directions.

In the 2015 IECC, however, the base maximum Prescriptive SHGC is also tied to glazing orientation. The base Prescriptive SHGC established in the 2015 IECC results in the exact same maximum permitted Prescriptive SHGC for northern-oriented fenestration with a wide projection (PF > 0.50) as that permitted for fenestration oriented to the south, east or west with the same PF.

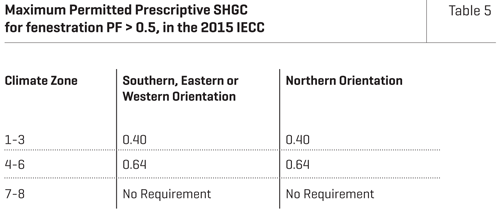

Tables 4 and 5 indicate the variation of maximum Prescriptive SHGC permitted for commercial buildings, based upon climate zone, projection factor and fenestration orientation.

Use of the Prescriptive Path in commercial buildings is limited to buildings where the vertical glazing and skylight area do not exceed certain limits. Beginning with the 2012 IECC, these limits became dependent upon whether or not automatic daylighting controls were provided in the daylight areas of the building. These controls reduce the artificial lighting load when daylighting is provided to a room or space. Combining automatic daylighting controls with well-placed fenestration allows fenestration to have a positive impact on the overall energy use of the building by reducing the lighting load during daylight hours.

If a building is equipped with automatic daylighting controls, having at least 50 percent of the conditioned floor area in a daylight zone, and glazing with a VT/SHGC ratio > 1.1, then 40 percent of the above-grade wall area is permitted to be fenestration area. If this criterion is not met then the fenestration area is limited to 30 percent of the above-grade wall area. Those parts of exterior walls not included in the calculation of the Window to Wall Ratio (WWR) must meet the requirements of the 2015 IECC for opaque walls. For example, in order for those parts of a curtain wall system glazed with opaque glass to be excluded in the calculation of the WWR, they must be insulated as required for other metal framed opaque walls in the building’s exterior envelope.

Up to 5 percent of the roof area is permitted to be skylights where a building is equipped with automatic daylighting controls. However, under the Prescriptive provisions of the 2015 IECC, skylights may not exceed 3 percent of the roof area in buildings without such controls. Minimum skylight area requirements began with the 2012 IECC. These provisions require at least half the floor area be toplit where spaces are directly under a roof; larger than 10,000 square feet; have ceilings in excess of 15 feet; and are used for offices, lobbies, atriums, concourses, corridors, storage areas, gymnasiums/exercise centers, convention centers, automotive service centers, manufacturing areas, non-refrigerated warehouses, retail stores, distribution/sorting areas, transportation areas and workshops.

The 2015 IECC requirements apply to spaces larger than 2,500 square feet, rather than 10,000 square feet. The provisions have also been expanded to allow for sidelighting by vertical glazing. The 2015 IECC requires all of the daylighting requirements, however, to either be met by toplighting or sidelighting. It does not include provisions to permit a combination of both toplighting and sidelighting to meet the requirements.

The 2015 IECC requires air leakage resistance of windows, door assemblies and unit skylights to be determined in accordance with NAFS-11 or NFRC 400-09, similar to the requirements in the 2012 IECC. The 2015 IECC also requires air leakage resistance of curtain wall, storefront glazing and commercial doors to be determined in accordance with ASTM E283-04.

Editions of the IECC prior to 2012 used the same pass/fail criteria for air leakage of windows, doors and unit skylights in commercial buildings as that established by NAFS. The 2012 IECC, however, established more stringent criteria than that previously in place for certain Performance Classes. This has been maintained in the 2015 IECC. Specifically, the maximum air leakage rate permitted for windows, sliding and swinging doors and unit skylights without condensation weepage openings in the 2012 and 2015 IECC is 0.2 cfm/sq. ft. when tested at 1.57 psf. The maximum air leakage rate permitted by NAFS for some Performance Classes of fenestration is 0.3 cfm/sq. ft. when tested at the same pressure.

The 2015 IECC includes a new variation of the Prescriptive Path called the Assembly U-factor, C-factor or F-factor Based Method, which permits some tradeoffs between the U-, C- and F-factors of various components of the building envelope and glazed area (both vertical glazing and skylights). The U-factor pertains to opaque walls, roofs and fenestration. The C-factor pertains to below-grade walls. The F-factor pertains to the perimeter of slab-on-grade floors. For example, an increase in permitted vertical fenestration area can be obtained by increasing the insulation provided to slab-on-grade floors or below-grade walls. Although the method is new to the 2015 IECC, it has previously been used successfully in some U.S. jurisdictions.

Emergency escape and rescue openings

The 2015 IBC requires emergency escape and rescue openings in sleeping rooms below the fourth floor of a building, and in all basements. There are exceptions for rooms in buildings that are fully equipped with a fire sprinkler system, rooms that open directly to a corridor that leads to an exit in two directions, and basements less than 200 square feet used only to house mechanical equipment.

Typically the emergency escape and rescue opening requirements are met with operable windows or doors. Operable skylights and roof windows are also permitted to be used, if they meet the size requirements and the bottom of their opening is within 44 inches of the floor below.

The requirements for sizes, locations, etc., are set forth in Section 1030 of the 2015 IBC. It is important to note that the required opening size of 24 inches high, 20 inches wide and 5.0 or 5.7 square feet in area must be met by “normal” operation of the window, door or skylight without the use of keys, tools or special knowledge and without the removal of a second sash from the opening.

Minimum window sill heights

The 2015 IBC contains requirements for minimum sill heights for operable windows in apartments, townhouses, duplexes and single-family homes. Section 1015 requires the bottom of openings created by these windows to be a minimum of 36 inches above the adjacent interior floor when they are 72 inches or more above grade.

There are multiple exceptions, however, to this requirement. The minimum sill height does not apply to windows that do not open more than 4 inches or that are equipped with window guards that comply with ASTM F2006-10 or ASTM F2090-08 or window opening control devices (WOCD) that comply with ASTM F2090-08. WOCDs must limit the initial opening of the window to no more than 4 inches, and must also be releasable with no more than 15 pounds of force so that these kinds of windows can be used to meet the Emergency Escape and Rescue Opening requirements of the 2015 IBC.

Means of egress doors

Section 1010.1.5 of the 2015 IBC restricts the threshold height of the required exit door in residences and dwelling units to ¾ inch for sliding doors and ½ inch for other doors, as measured from the top of the threshold to the floor or landing on each side of the door. The rise from floor or landing to the top of the threshold at other exterior doors in multi-family or low-rise, residential occupancies that are not required to be accessible or which do not provide access to a Type A or Type B unit is permitted to be up to 7 ¾ inches by Section 1010.1.7. This is the same height as that permitted for the riser height for stairs. Exterior living spaces such as decks or balconies that serve Type B units require the same threshold heights as exit doors.

It should be noted, however, that all dwelling units in a multi-family building that has more than four dwelling units, and all sleeping units in hotels or motels that have more than four sleeping units, must be a Type B. Furthermore, the U.S. Access Board has ruled that if there is an exterior living area that serves that unit, it must also meet the criteria for a Type B unit. This applies to the door between the exterior living space, such as a deck or balcony, and the interior space. Therefore, the provision that permits a threshold height of up to 7 ¾ inches often does not apply to exterior balcony doors serving residential spaces, such as apartments or hotel sleeping rooms.

The 2015 IBC permits a step down of up to 4 inches from an interior, Type B space to an exterior deck or balcony serving that space. The threshold of a door between those two spaces is permitted to be up to 4 ½ inches for swinging doors or 4 ¾ inches for sliding doors, as long as it is not more than ½ or ¾ inch, respectively, above the interior floor. If the difference between the top of the threshold and the top of the floor on the interior side is greater than ¼ inch then the floor level change must be beveled with a slope of not greater than one unit vertical for every two units horizontal.

Window installation

Section 1405.4 of the 2015 IBC requires window openings to be flashed “in such a manner as to prevent moisture from entering the wall or to redirect it to the exterior.”

Safety glazing

Section 2406.4 of the 2015 IBC establishes the locations where safety glazing is required. They include the following:

- Glazing in and near swinging and sliding doors

- Large lites of glass (more than 9 square feet) near walkways

- Glazing around tubs, showers, pools and similar fixtures

- Glazing near stairways, ramps and the landings for both.

In these applications, the glazing must be labeled per the Consumer Product Safety Commission CPSC 16 CFR 1201 requirements. There are some exceptions for applications that are considered less hazardous, such as very small openings (less than 3 inches in diameter) in doors, decorative glass and glazing provided with a protective bar, etc.

The previous exception for wired glass in fire-rated assemblies that complied with ANSI Z97.1 in other than educational-use groups has been removed. In the 2015 IBC, only wired glass that meets CPSC 16 CFR 1201 is permitted in doors.

The 2015 IBC also permits the use of glass that meets the two most stringent categories of ANSI Z97.1 in hazardous locations, as defined by those codes, but which do not fall within the scope of the federal law established by CPSC 16 CFR 1201. These locations include tub and shower enclosures, door sidelites, large lites of glass, and glazing near stairs, ramps and pools.

The criteria for these two categories of ANSI Z97.1 are similar to CPSC 16 CFR 1201 for these applications, but ANSI Z97.1 was updated in 2004, while CPSC 16 CFR 1201 was last updated in 1977. Therefore ANSI Z97.1 is considered to be more up-to-date and consistent with products currently available.

The defined hazardous locations did not change significantly between the 2012 International Codes and the 2015 International Codes.

Replacement windows

As a general rule, when an addition is made to a building or a component within a building is replaced, the International Codes require the new component or addition to comply with the requirements of the current code for new construction. This is also true for replacement windows, with one exception.

The 2015 IBC contains special provisions for the installation of replacement windows in openings where Emergency Escape and Rescue Openings are required. In some cases the opening is not large enough to accommodate an operable window that meets the size requirements. In those cases an alternate size operable window can be installed, as long as it meets the following criteria:

- The replacement window is the manufacturer’s largest standard-size window that will fit within the existing frame or existing rough opening.

- The replacement window is the same operating style as the existing window or a style that provides for an equal or greater window opening area than the existing window.

- The replacement window is not part of a change of occupancy.

- The 2015 IECC requires replacement windows to comply with the energy conservation requirements for fenestration in new construction. This requirement applies whether the entire window unit (including frame, sash and glazing) is being replaced, or just the sash and glazing.

Glass design

Chapter 24 of the 2015 IBC references ASTM E1300-12AE01 for glass design. The 2012AE01 edition of ASTM E1300 addresses several types of glass layups and support combinations. Having it referenced in the 2015 IBC greatly enhances the designer’s options in terms of providing glazed openings that can meet all the requirements of the code, including energy efficiency and impact resistance.

If the framing supporting the glass deflects 1/175 of the length of the edge of glass being supported, or ¾ inch, the 2015 IBC requires the glass to be designed by a registered design professional. An exemption to this requirement is given in Section 1709.5 of the 2015 IBC for exterior windows and doors that are tested and labeled in accordance with NAFS-11.

Skylights and sloped glazing

The 2015 IBC has different requirements for factory-built unit skylights than for other types of glazed assemblies in roofs such as skylights and sloped glazing. Factory-built unit skylights that contain only one panel of glazing material are required to be tested and labeled for performance grade in accordance with NAFS-11 in the 2015 IBC. Section 2405.5 of the 2015 IBC establishes the required performance-grade rating for wind, snow and dead loads.

As for vertical glass, glass in sloped glazing is to be designed in accordance with ASTM E1300-2012AE01. The requirements for screening under skylights and sloped glazing, as set forth in Section 2405.3 of the 2015 IBC are consistent with previous editions of the International Codes. Screening must be securely fastened to the framing and be able to support twice the dead weight of the glass. Requirements for curbs on skylights and sloped glazing, when applicable, are also consistent with those in the previous editions of the International Codes and are set forth in Section 2405.4 of the 2015 IBC.

Code cycles

Typically, the greatest rate of adoption and enforcement of a new edition of the International Codes occurs in the second and third year after publication. There are also some states that specifically chose to update the edition of the model code they are enforcing every six years instead of every three. So they may skip adoption of the 2015 edition entirely and wait until the 2021 becomes available. Although we can expect to see increased enforcement of the 2015 I-codes in 2017, other jurisdictions will continue to enforce the 2012 or earlier editions, with or without significant amendments. This inconsistency makes achieving code compliance for fenestration products a challenge, particularly for those manufacturers who offer products over several states or nationwide. The reader is therefore encouraged to verify the applicable code edition and amendments in place at the outset of a project.