- Project: 700 Santana Row, San Jose, CA

- Products: Solarban® 70 Glass

- Architect: WRNS Studio

- Vitro Certified ® Fabricator: Glassfab Tempering Services

- Glazing Contractor: Walters & Wolf

- Photographer: Bernardo Grijalva

- LEED® Silver Certification

Now more than ever, architects, developers and construction professionals are turning their attention to embodied carbon – the carbon emissions produced during the manufacturing, transportation and installation of building materials. Glass plays a critical role among these materials, both as a design staple and as an opportunity for meaningful carbon reduction.

Now more than ever, architects, developers and construction professionals are turning their attention to embodied carbon – the carbon emissions produced during the manufacturing, transportation and installation of building materials. Glass plays a critical role among these materials, both as a design staple and as an opportunity for meaningful carbon reduction.

But how significant is embodied carbon in glass, and why is lowering it so crucial in commercial building construction?

Understanding Embodied Carbon in Glass

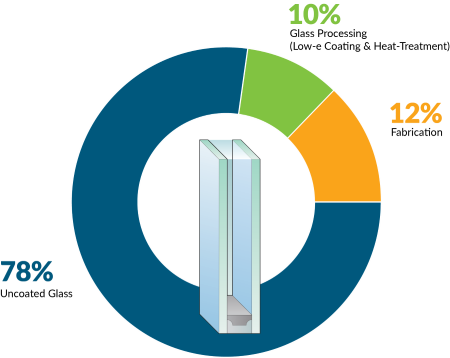

While glass provides many benefits to modern architecture — aesthetic appeal, daylighting abilities and energy performance — its production is energy-intensive. The vast majority of the carbon, approximately 78%, is in the uncoated flat glass. Of the remaining embodied carbon, approximately 12% is created by the insulating glass unit (IGU) fabrication process, and 10% comes from the heat-treatment process and adding energy efficient low-emissivity (low-e) coatings.

While glass provides many benefits to modern architecture — aesthetic appeal, daylighting abilities and energy performance — its production is energy-intensive. The vast majority of the carbon, approximately 78%, is in the uncoated flat glass. Of the remaining embodied carbon, approximately 12% is created by the insulating glass unit (IGU) fabrication process, and 10% comes from the heat-treatment process and adding energy efficient low-emissivity (low-e) coatings.

The metric used to measure embodied carbon is Global Warming Potential (GWP), expressed as kilograms of equivalent carbon dioxide (CO₂-eq). Lower GWP values indicate more sustainable products, which are increasingly in demand as governments and industries set ambitious carbon reduction targets.

Why Lowering Embodied Carbon Matters

1. Achieving Sustainability Goals

For architects and developers working toward LEED® certification, WELL certification or other sustainability standards, reducing embodied carbon is key. The U.S. General Services Administration (GSA) now requires building materials, including glass, to meet strict Low Embodied Carbon (LEC) thresholds.

2. Reducing Environmental Impact

Reducing embodied carbon directly lowers the overall environmental impact of a construction project. For example, choosing LEC glass products like those offered by Vitro Architectural Glass can significantly reduce a building’s contribution to global emissions. Over time, widespread adoption of LEC materials could help curb the impacts of climate change.

3. Future-Proofing Commercial Constructions

With increasing legislation targeting embodied carbon emissions, specifying LEC products ensures compliance not only today but for years to come. Adopting these materials now helps future-proof projects, avoiding costly retrofits or regulatory challenges in the future. Современные игроки всё чаще выбирают онлайн-платформы, где удобно сочетать развлечения с безопасностью. Доступны разнообразные слоты, настольные игры и игры с живыми дилерами, а регистрация и вход проходят быстро и просто. Финансовые операции поддерживаются проверенными методами, а мобильная версия позволяет наслаждаться играми с любого устройства. В центре внимания пользователей оказывается casino , обеспечивая стабильную работу сайта, удобный интерфейс и высокий уровень защиты данных для комфортного игрового процесса.

Key Strategies for Reduction

At Vitro, we’ve implemented innovative strategies to lower the embodied carbon of our products without compromising their quality and performance.

1. Increased Use of Recycled Cullet

Recycled cullet, or broken and unused glass, reduces the need for raw material extraction and lowers the energy required for production. It can account for more than 20% of new glass products, significantly reducing both emissions and waste.

2. Oxy-Fuel Furnace Technology

Using oxy-fuel technology in glass production enables cleaner, more efficient combustion compared to traditional methods. This innovation can reduce greenhouse gas emissions by up to 50% and decrease energy consumption in melting furnaces by up to 20%.

3. Optimized Manufacturing Processes

Efficient manufacturing practices, such as advanced furnace control systems and the adoption of low-energy lighting in facilities, contribute to further reductions in energy use and emissions. Vitro’s consistent investment in these processes ensures our glass maintains its high performance while minimizing its carbon footprint.

4. Environmental Product Declarations (EPDs)

Our transparent commitment to sustainability is reflected in our third party-verified Environmental Product Declarations (EPDs). These documents provide architects with reliable data on our glass products' life cycle impacts, from raw material extraction through production and post-use disposal.

A Whole Building Approach

While specifying LEC glass is crucial, it is even more impactful when considered as part of a whole-building strategy. High-performance glass products, like those with low-e coatings, optimize energy efficiency by reducing operational carbon emissions in HVAC and lighting systems. Combined with improved durability and extended service life, these glass systems create lasting value for building owners while helping to preserve the environment.

Vitro's Commitment to Sustainability

With a GWP value of less than 1,331 CO₂-eq/kg, all Vitro Architectural Glass products meet the GSA’s Top 20% ("Most Preferred") LEC material category. This lowest embodied carbon designation applies to all Vitro-produced architectural glass from all Vitro plants all the time. With this designation, Vitro is proud to lead the way in carbon-conscious innovation and we remain dedicated to creating a sustainable future for the built environment.

Learn more about Vitro's low-carbon solutions today by visiting VitroGlazings.com/sustainability.