Q+A with Biesse | One Company, One Vision

Elevating glass fabrication through quality, technology and seamless support

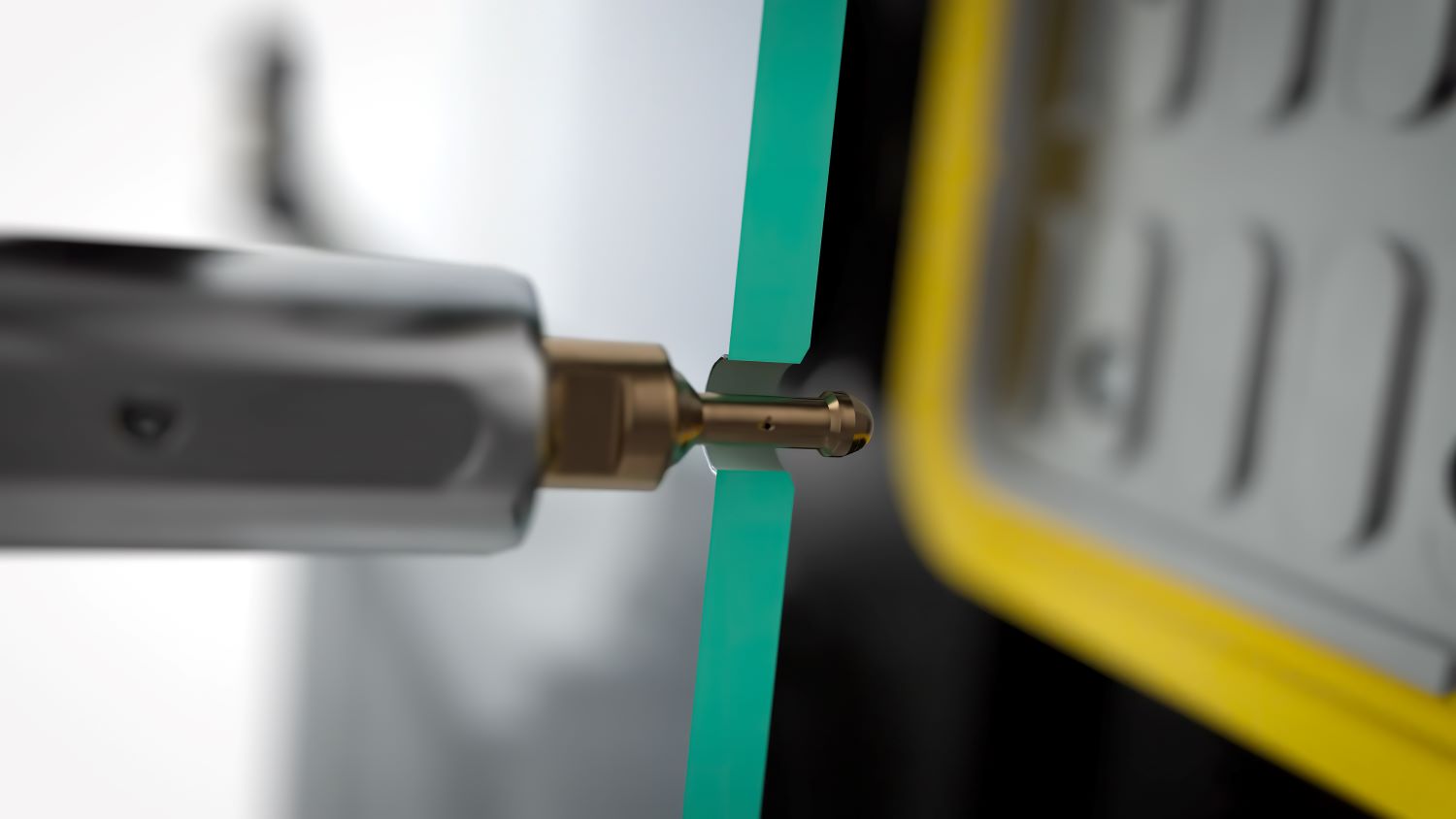

Above: The Helix drill by Biesse allows drilling, milling and countersinking from one side of the glass without blow outs. Photo courtesy of Biesse.

Biesse is embarking on a transformative journey to reshape its presence in the North American glass market through a bold consolidation and rebranding effort that unites several respected industry names—Bavelloni, Intermac, Forvet, Movetro and Busetti—under the singular Biesse umbrella. This strategic move is designed not only to simplify the customer experience and unify the company’s extensive expertise and innovative integrated solutions, but also to position Biesse as the go-to manufacturer for high-quality, multi-material machinery solutions. Central to this vision is a commitment to innovation, exemplified by advancements like the SOPHIA IoT platform and the development of new machine technologies that enhance precision, efficiency and sustainability. Through streamlined operations, enhanced after-sales support and robust training, Biesse aims to maintain the trust of legacy customers while driving the glass industry forward with smarter, integrated solutions tailored to the evolving demands of modern fabricators.

Biesse is embarking on a transformative journey to reshape its presence in the North American glass market through a bold consolidation and rebranding effort that unites several respected industry names—Bavelloni, Intermac, Forvet, Movetro and Busetti—under the singular Biesse umbrella. This strategic move is designed not only to simplify the customer experience and unify the company’s extensive expertise and innovative integrated solutions, but also to position Biesse as the go-to manufacturer for high-quality, multi-material machinery solutions. Central to this vision is a commitment to innovation, exemplified by advancements like the SOPHIA IoT platform and the development of new machine technologies that enhance precision, efficiency and sustainability. Through streamlined operations, enhanced after-sales support and robust training, Biesse aims to maintain the trust of legacy customers while driving the glass industry forward with smarter, integrated solutions tailored to the evolving demands of modern fabricators.

Glass Magazine sat down with Michele Ragno, sales director, Glass and Stone, and Ronald Lorick, sales manager, Lines Glass, to discuss how Biesse is simplifying the manufacturing process and how industry professionals can benefit from the company’s digital technologies and smart automation that are reshaping modern manufacturing.

Glass Magazine: Biesse recently consolidated several brands, including Bavelloni, under one umbrella. What is Biesse’s strategic reasoning behind this rebranding and new vision for the North American glass market?

Michele Ragno: The rebranding is the beginning of getting the industry used to the Biesse name as a supplier of high-quality machines for many different materials. The Biesse name is very well established in the wood materials industry, and while the Intermac, Forvet, Bavelloni, Movetro and Busetti brands are well known and highly respected in the glass industry, continuing to sell under many different brand names distracts from the whole picture—Biesse as the brand for all machine solutions for multiple materials. With the launch of the new Biesse machinery portfolio, the machines were refreshed with upgraded features, a unified naming structure, and Biesse’s new corporate identity and colors—reflecting a renewed commitment to innovation and design consistency.

GM: What do you want North American customers to know after this restructuring?

MR: Although the names may change, the machines have not. The talent that produces the equipment is the same and the quality will only improve. Through acquisition, Biesse now owns the factory, ensuring full accountability and control over production and service. By consolidating resources at the factory level, technology crossover is enabled, as well as spare part standardization and technician and support staff cross-training, increasing the overall expertise of sales, customer service and technical support.

GM: What have been the most significant challenges and opportunities during this rebranding and integration process?

MR: Integration can be a slow, arduous and very complicated process. Different control systems, operator interfaces, factory locations, historical databases and the like are very complex to combine. These efforts must be made expertly. Our focus is to minimize delays and disruptions throughout the transition. Unfortunately, some disruptions may happen and impact customers, but we are committed to resolving these instances as swiftly as possible.

GM: For customers used to the old brands and company structure, how is Biesse working to address market confusion of retiring legacy brand names, while maintaining loyalty and trust during this transition?

MR: By being as transparent as possible, while transitioning existing talent to new roles within the company. Although the phone numbers and email addresses have changed, a redirect has been put in place to maintain seamless communication and minimize any disruption for customers during this transition.

GM: Beyond machine sales, what primary benefits do Biesse’s customer support and training services offer to glass fabricators? How do you ensure your customers are getting the most out of their investment?

MR: Being a one-stop-shop means that we “own the problem,” we are the factory, no finger pointing. When complete, customers will call for sales, support, parts or tooling and we can handle it all.

GM: The rebrand positions Biesse as an “international native” company, but what does that mean for market support in North America, and how does it ensure Biesse can meet the unique needs of customers around the world?

MR: Biesse has always been an international native company. The combination of brands has brought new companies into our family. Biesse works on a hub/spoke relationship with factories in Italy and with fully self-reliant subsidiaries worldwide. Our customers can rely on the local subsidiary for all their needs and if factory assistance is needed, we handle it internally. The tech that handles the issue and receives support from the factory is trained to handle the problem the next time it happens, without needing factory support again. The information is also added to the database and all techs locally can access it.

Responding to innovation

GM: The rebrand is a signal of Biesse’s commitment to innovation. What new technologies are most relevant to the glass industry?

MR: One of the first innovations that we have developed is the waste management system for the Multi Pro Vertical machines, which allow large corner cutouts to be processed on vertical machines. Our unique suction carriage design affords greater handling of the remnants.

Sophia Parts allows customers to access parts drawings, pricing and availability directly. The shopping cart feature allows you to buy parts after hours.

Sophia IOT uses a full-time connection to our servers to notify us of errors in connected machines for faster support and preventative maintenance of the machine. Dashboards give managers the ability to see the up/idle/down time of the machines in real-time.

GM: The rebrand is a signal of Biesse’s commitment to innovation and the new Biesse Material Hubs are a key part of the rebrand. What kind of hands-on experience can a glass manufacturer expect at one of these hubs?

MR: The Material Hubs bring the customer into the full Biesse experience. Customers see how Biesse provides solutions across glass, wood, stone, and advanced materials and metal industries. In-person machine demos are done on available machines. If a particular machine is not in the current location, we can link to another location with the machine virtually. Interactive screens and technology “boxes” enable the sales manager to walk through the machine options while showing video or drawings of the machines/options and building the machine to their specifications.

GM: What percentage of service issues can you resolve remotely for glass machinery through your Remote Assistance Package, centered around SOPHIA? What kind of impact has this had on customer uptime?

MR: Most issues can be diagnosed via the internet using our Remote Assistance Program. Having PC-based CNC controllers allows greater access to both the CNC and PLC side of the machine, quickly finding what is faulty and needs attention.

GM: How does the new Human Machine Interface simplify the production process and improve the user experience for a glass fabricator?

MR: The new HMI makes machine operation and employee training much simpler. A single interface means cross-training between cutting, drilling and CNC machines is quite fast since it’s the same platform regardless of the process.

GM: There has been mention of a revised product portfolio and nomenclature launch without introducing completely new machines. Are there any specific new configurations or technologies that customers should be excited about despite the name changes?

Ronald Lorick: Absolutely! Customers should be excited because adding Bavelloni to our portfolio strengthens what Biesse already stands for: precision, reliability and innovation. Bavelloni’s machines bring world-class glass-processing expertise, which complements our existing solutions and allows us to offer customers a more complete, high-performance range. Together, we can provide even greater flexibility, efficiency and value to meet diverse customer needs.

GM: How does Biesse’s commitment to sustainability, as part of its rebrand, align with the growing demand for environmentally responsible practices in glass manufacturing and glass processing machinery? Are there specific examples of features or technologies that help customers reduce their environmental impact?

RL: Biesse’s commitment to sustainability is a central part of our rebrand and aligns directly with the increasing demand for environmentally responsible practices in glass manufacturing and processing machinery. By integrating sustainable solutions into both our operations and our product offerings, we help customers reduce their environmental impact while maintaining high performance and precision.

For example, many of our glass and stone processing machines utilize water jet cutting systems that operate within closed-circuit purification systems, allowing water to be reused in the production process and minimizing overall consumption. This not only conserves a critical resource but also demonstrates responsible operational practices. Through these technologies, practices and training initiatives, Biesse empowers customers to adopt more efficient, environmentally friendly production methods while benefiting from the precision, versatility and reliability of our machines.

GM: Beyond your existing service plans, is Biesse exploring new initiatives or technologies, such as big data and predictive analytics, to enhance predictive maintenance and minimize unplanned machine downtime?

RL: Biesse is actively exploring and implementing advanced technologies like big data and predictive analytics to enhance predictive maintenance and minimize unplanned machine downtime. Biesse has embraced smart factory technologies, utilizing AI and machine learning to analyze data collected from IoT devices. This approach helps predict maintenance needs, optimize production schedules and improve product quality, contributing to reduced downtime and enhanced operational efficiency. These initiatives align with Biesse’s commitment to innovation and sustainability, ensuring that our customers benefit from cutting-edge solutions that enhance machine reliability and performance.

GM: What role has your product development team played in this rebranding, and how have they balanced innovation with continuity?

RL: Our product development team has played a central role in the rebranding, ensuring that innovation and continuity go hand in hand. They have focused on enhancing existing products, integrating new technologies, and improving performance, all while maintaining the reliability and precision that our customers expect from Biesse. This approach ensures that the rebrand reflects a modern, innovative Biesse while honoring the legacy of our established solutions.

GM: Biesse showed its Intermac Edge Up and Intermac Cut Go at GlassBuild this year. How do these machines address the evolving needs of glass fabricators, particularly in terms of handling large, heavy glass and improving efficiency?

RL: Intermac Edge Up and Intermac Cut Go are designed to address the evolving demands of glass fabricators by combining precision, efficiency, and ease of handling.

Intermac Edge Up excels in processing large and heavy glass panels with superior stability and safety, reducing the physical strain on operators while maintaining high precision for edge finishing. Its automated handling systems and optimized workflow help fabricators increase throughput and consistency.

Intermac Cut Go focuses on efficient glass cutting while handling oversized panels with ease. Its advanced control systems and streamlined setup reduce waste, minimize manual handling, and allow fabricators to improve productivity and turnaround times.

Together, these machines reflect Biesse’s commitment to helping fabricators work smarter, handle larger panels safely, and operate more efficiently in today’s competitive market.

Looking forward

GM: What significant trends, emerging technologies or market trends do you believe will have the biggest impact on manufacturing, and how is Biesse adapting its R&D and product roadmap to prepare for them?

RL: Several significant trends are shaping the future of manufacturing, particularly in the glass industry, including automation, customization and sustainability. These trends are driving demand for more efficient, flexible and environmentally responsible solutions, while advanced processing technologies are becoming critical for competitiveness.

To address these developments, Biesse has strategically invested in Bavelloni and Bavelloni tools, expanding our portfolio with versatile, high-performance solutions. Our R&D roadmap focuses on integrating smart technologies, predictive maintenance and flexible machinery, ensuring that our customers can meet evolving production requirements, improve efficiency and stay ahead in a competitive market.

GM: Looking forward, what’s next for Biesse? How will the “One Company” foundation you’ve built help you to adapt to future market changes and continue to meet customer needs?

RL: Biesse is focused on strengthening its global presence, expanding its product portfolio and driving innovation to meet the evolving needs of our customers. The “One Company” foundation which unites Biesse, Intermac, Bavelloni, Forvet and Movetro under a single strategic vision enables us to leverage shared expertise, streamline R&D and deliver integrated solutions across multiple markets.

This approach allows us to respond quickly to emerging trends such as automation, customization and sustainability, while maintaining high standards of quality, efficiency and customer support. At the heart of our strategy is a strong commitment to customer care: we ensure customers receive reliable guidance, proactive support and tailored solutions to maximize their success. By combining the strengths of our brands and prioritizing our customers, Biesse remains agile, innovative and fully equipped to support our customers’ needs, today and in the future.