What to know about finished flat sheet aluminum: high quality, high performance and available

Get the right product from the right provider

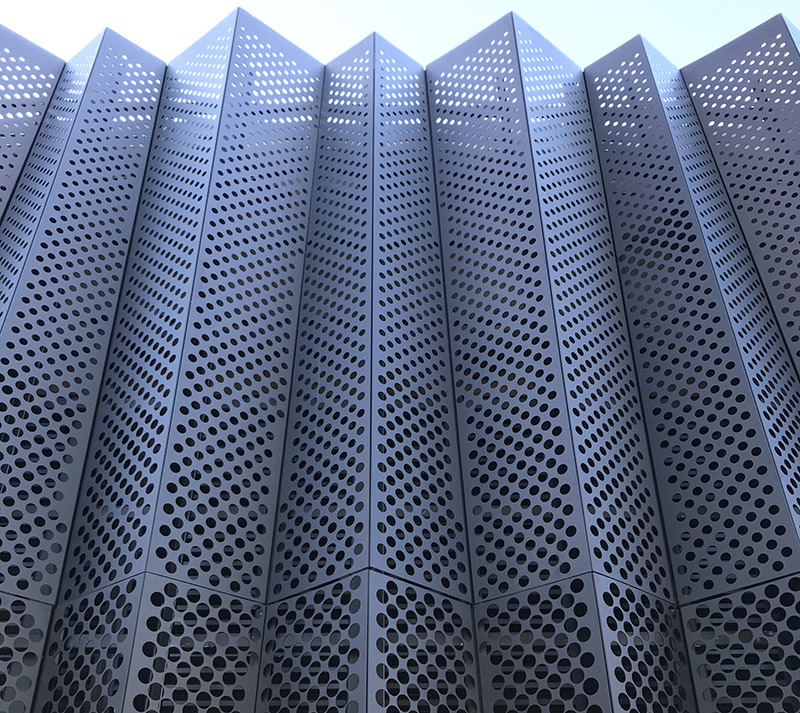

When you think about finishing for fenestration, do you imagine window frames in shades of white or black, a multi-story curtainwall in metallic silver, doors in dark brown or maybe colorfully painted storefront framing? In commercial, institutional and multi-family buildings, aluminum extrusions often are the material used for the fenestration framing.

Now, picture the finished-to-match perimeter trim and panning surrounding the window and entrance systems, the curtain wall and window wall infill panels, exterior wall cladding, coping and soffits, and decorative accents. These products typically are formed from flat sheets of aluminum.

Schedule all aluminum to be batch processed

Choosing a single source finishing service provider will help you ensure a consistent appearance across multiple products in nearly any color. For greater assurance, you can request and schedule all the material for a project to be finished together as a batch.

Like extrusion profiles, aluminum flat sheets also are racked to move through the factory’s finishing lines. Larger sheets require more points of contact than smaller ones. Be aware that rack marks occur where the paint or anodize cannot penetrate the contact points holding the aluminum sheet to the rack. Talk with your finisher to understand how these marks are positioned so that that your formed product will conceal them from view once they are installed on the building.

Choose an environmentally responsible finishing service provider

As with extrusion profiles, aluminum flat sheets also can be painted or anodized to meet the same high-performance specification standards. For exterior applications, AAMA 2605 for paint and AAMA 611 for Class I anodize reflect the industry’s most stringent specification standards.

Along with quality assurance standards for appearance and performance, a single source finishing partner can offer both painted and anodized flat sheet to achieve your project’s sustainability goals. Environmentally responsible finishing service providers use proper processes and equipment to safely prepare and apply architectural coatings in their facility. After the finished material leaves the facility, there are no adverse environmental effects from “off gassing” on your project’s indoor air quality and no health concerns for the occupants.

Need flat sheets fast? Some are available for accelerated delivery

Some finishers stock flat sheet in standard colors and sizes that are available on an accelerated delivery schedule and in small quantities. These can be an ideal solution if you have a fast-track project that does not require matching extrusion and sheet, and for renovation projects. Remember to plan on longer lead times for specialty finishes, such as micas, metallics, textured, antimicrobial-infused or custom-matched coatings.

You should expect your finished material to arrive damage-free. Flat sheets present a larger surface area and a greater potential for scratches or dings during shipping and handling. Most finishers will apply a removable film for extra protection as the material journeys to the jobsite. If you plan to store your flat sheet for more than a few days, discuss long-term protective packaging with your finishing partner.

A single source provider can coordinate your finished material performs as specified, arrives as scheduled and delivers the desired appearance for your project.