Heat-Treated Glass Surfaces are Different

Industry cleaning procedures to avoid glass damage

Heat-treated glass is a critical component of high-performance coated, insulating, laminated, spandrel, safety glazing, bullet-resistant, blast-resistant and hurricane-resistant fenestration products. Heat-treated glass usage has increased in recent years as a result of changes in the building codes requiring safety glazing in more applications, the need to meet higher thermal stress loads due to the use of more high-performance glass and coatings with increased heat absorbing and/or reflecting properties, larger glass sizes, and increased design loads.

Heat-strengthened, fully tempered

There are two types of heat-treated glass as defined in ASTM International’s C1048 Standard Specification for Heat-Strengthened and Fully Tempered Flat Glass. The two types are heat-strengthened and fully tempered.

Heat-treatment process

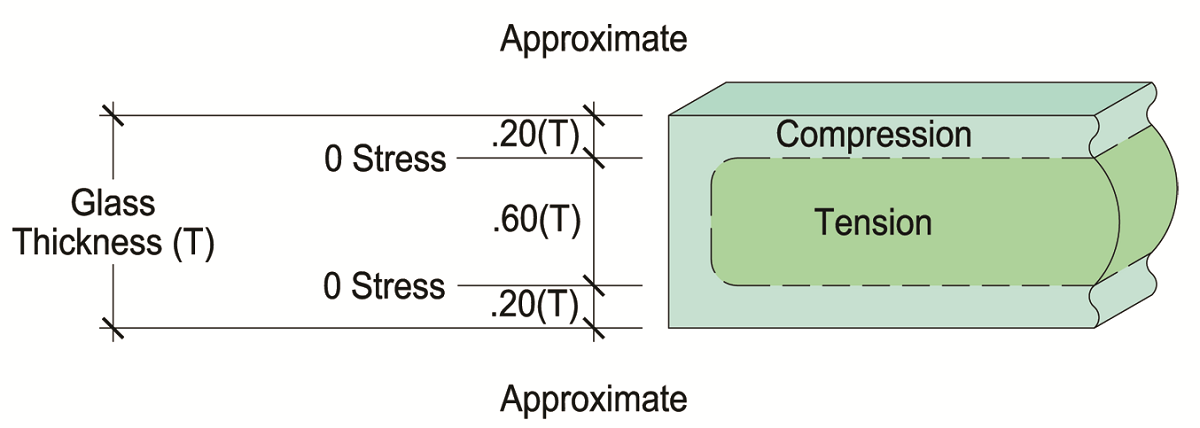

Both types of heat-treated glass are produced using the same equipment, typically horizontal roller hearth ovens using either a batch or continuous process. To prepare annealed glass for the heat-treatment process, it is cut to the required final size, the edges are treated according to the specified finish (commonly seamed or polished) and the glass is washed. The glass is then transported on horizontal rollers through an oven, where it is heated to approximately 1150 degrees Fahrenheit (621 degrees Celsius). Upon exiting the oven, the glass is rapidly cooled (quenched) by blowing air uniformly onto both surfaces simultaneously. The cooling process leaves the surfaces of the glass in a state of compression, and the central core in compensating tension (see Figure 1).

Properties of heat-treated glass

The color, clarity, chemical composition, light transmission, hardness, specific gravity, expansion coefficient, softening point, thermal conductivity, solar optical properties and stiffness remain unchanged by the heat-treating process. The properties that change are improved flexural and tensile strength and resistance to thermal stresses and shock. Under uniform loading, heat-treated glass is stronger than annealed glass of the same size and thickness. The heat-treating process will change the break pattern of glass that has been treated to a higher level of compressive stress, i.e., fully tempered glass that is designed to meet the industry safety glazing standards will break into relatively small pieces, thereby greatly reducing the likelihood of serious cutting or piercing injuries.

Heat-treated glass surfaces

The heat-treating process typically involves the transport of very hot glass on rollers. As a result of this soft glass-to-roller contact, some glass surface changes will occur. Minute glass particles (fines) from the glass cutting, edging and washing processes; typical manufacturing plant airborne debris or dust; refractory particles from the tempering oven roof; and external airborne dirt and grit carried into the plant by the large volumes of quench air used in the process may adhere to one or both glass surfaces. Also, the physical contact of the soft glass surface with the rollers may result in a marking or dimpling of the glass surface.

Glass quality specifications contained in ASTM C1036 Standard Specification for Flat Glass establish the size and number of glass imperfections allowed based on specific visual inspection criteria. The glass surface conditions described above are not usually visible to the eye under normal viewing, do not threaten the product’s structural integrity and are not a reason for rejection of the glass based on the industry ASTM consensus standards.

However, such surface conditions may be detectable to the touch despite being invisible. This difference in “feel” between annealed and heat-treated glass can lead to issues during cleaning of the glass, as glass cleaning workers attempt to remove microscopic particles. With the best intentions, they may attempt to scrape particles that can be felt but not seen and may end up scratching and chipping the glass surface.

Additionally, once the glass is delivered to the construction site and/or installed, construction materials and debris may be deposited on the glass surface. Paint, stucco, concrete, adhesives and other materials may be splattered on the glass and left for long periods of time.

How to clean heat-treated glass

The recommended cleaning procedures for heat-treated glass are identical to those for annealed glass. Scrapers, abrasives and harsh chemical cleaning agents are not recommended for any glass product because they can cause irreparable damage. Despite the best intentions, window cleaners may attempt to remove construction dirt and debris from the glass surface by scraping the surface. This can lead to glass damage, such as scratching and chipping, if microscopic particles adhering to the surface become dislodged and are transported across the glass surface during the scraping process.

Resources

Acceptable cleaning procedures are available from glass manufacturers and fabricators. The National Glass Association, with the International Window Cleaners Association, offers Glass Technical Papers that are free to download in the NGA Store.