Glass can become contaminated on a building site during construction. The main culprits are concrete slurry and cement dust, which if left unchecked, can cause etching and pitting, necessitating costly replacement. To minimize risk of damage and to ensure glass is intact for the final builders’ clean, it needs to be protected on the jobsite.

Protection products

Applied film on the exterior façade

This type of protection is either applied as a film or sprayed on with an airless sprayer onto the exterior façade. It does a good job with full protection against concrete slurry spills and scratches. However, the protective films or sprays require manual installation on the exterior of the building and are labor-intensive, both on the install and upon removal, and only provide protection through the construction phase of the project.

Applied film or airless sprayer applications make sense on one- or two-story buildings. However, taller structures would require equipment and extensive labor to achieve coverage, and after-completion disposal of the film can be expensive and not environmentally friendly.

Liquid-based coatings

- Silicone-based coatings

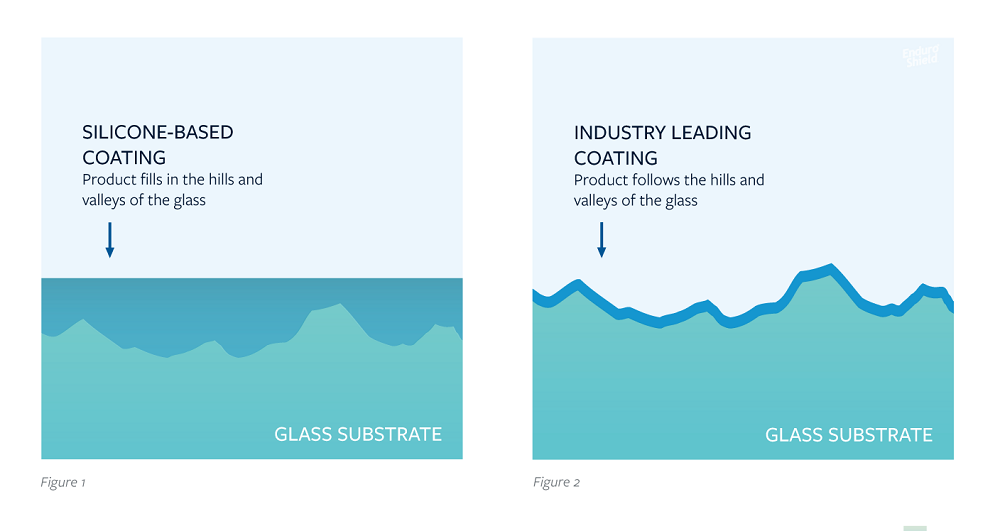

Silicone-based protective coatings can be applied either in the factory or after the glass has been installed. The coatings bond to the surface of the glass—most silicone-based products smooth the “hills and valleys” of the glass substrate, making it slippery and flat.

The coatings have water-repellent properties and help with soil buildup. Some also have oil-repellent properties. Most of the silicone-based coating products on the market require a one- to three-coat process to apply their product and may require maintenance application every one to two years. As with applied film, this could end up costing more in labor and would only be cost-effective on a one- or two-story building.

- Organosilane derivative

Organosilane derivative coatings can be applied in the factory or onsite before or after installation. The nanotechnology has both hydrophobic and oleophobic properties. It is a one-coat product that can be applied manually or with an automatic applicator, and it bonds to the hills and valleys on the surface of the glass. The coating doesn’t require any yearly additional coats to maintain the integrity of the product’s functionality, and it bonds to anodized aluminum as well as stainless steel.

Organosilane derivative coatings protect against cement slurry, staining and etching onto the glass and metal surfaces. They will also provide benefits after construction, protecting the glass against building runoffs, staining and corrosion, with low-maintenance and easy-clean advantages for many years.

- Polymeric resin

This product has both hydrophobic and oleophobic properties and offers good protection during the construction phase. It provides good protection; however, the excess polymer residue would need to be removed from the surface after the construction phase, which requires considerable additional labor, and often the residue removal is so difficult that it also removes the product as well.

How to pick the right product

Ask for verifiable test reports for every specification as part of the submittal process. Companies that can produce test reports to quantify their claims would be best suited to meet the specifications of any project. The size, makeup and parameters of a project would have to be considered.

Additionally, project managers should ask the following questions: What is the application method? Is there maintenance involved? Is it labor-intensive? What is the ROI? How long has the product been used, and do they have both new and long-standing projects and case studies supporting their technology?

Finally, be sure to read the fine print on the warranty. What does it entail? Does it require maintenance for the warranty to be valid? Not all companies hold themselves to the same standard and therefore not all warranties are equal.

Look for a product with the longest-lasting water and oil repellency that does not require revitalizer products to maintain the coating and warranty. Choosing a company and product that is reputable is very important in the construction industry. One bad choice could put the whole project at risk for damage or failure. Do your homework and discovery before you make a choice.