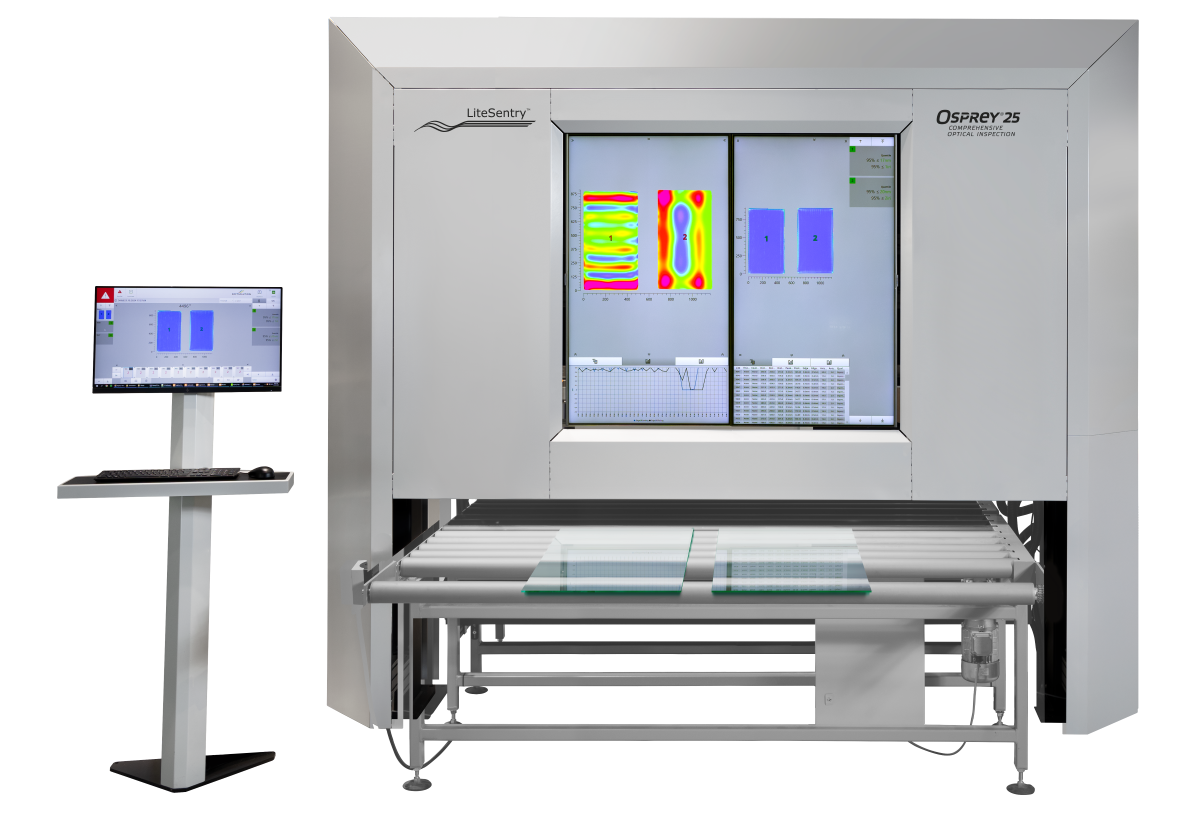

Above: The Osprey®25 distortion scanning system. Photo courtesy of LiteSentry.

Key Features

- Trusted distortion scanning

- Automated surface quality, dimensional, logo inspections

- Comprehensive optical inspection

- Seamless integration post tempering furnace

- Customizable user interface

The Osprey®25, the latest generation of LiteSentry’s flagship 360-degree distortion scanning system, offers automated inspection of surface defects, edge chips, white haze, logos and dimensions—all in a single, powerful platform.

The Osprey®25, the latest generation of LiteSentry’s flagship 360-degree distortion scanning system, offers automated inspection of surface defects, edge chips, white haze, logos and dimensions—all in a single, powerful platform.

Designed for seamless integration after the tempering furnace, the Osprey®25 helps glass fabricators meet tighter specs, reduce rework and elevate their quality standards—shift after shift. With a redesigned user interface, the real-time analytics delivers immediate insights to your process, allowing for higher quality and reduced risk.

From distortion to detail, all in one system

The Osprey®25 builds on over two decades of industry leadership in distortion and anisotropy measurement. The new system retains LiteSentry’s high-speed inspection of tempered flat glass immediately after the furnace, while now enabling detection of scratches and inclusions, coating defects and edge chips, incorrect or missing logo markings, and dimensional deviations (length, width, drill hole position). All results are processed and displayed through a newly designed, fully customizable user interface and stored in a SQL-based quality archive. This enables operators and plant managers to identify, trace and respond to quality issues quickly.

Trusted by leading fabricators

With over 3,000 systems installed in 61 countries, LiteSentry-Softsolution are the industry leaders in quality inspection. The Osprey Series of tempering inspection systems is trusted by top architectural, residential and specialty glass fabricators.The Osprey®25 continues this legacy by offering powerful integration into existing tempering lines, with real-time pass/fail logic, automatic alarms, and seamless compatibility with ERP and MES environments.

Supporting process control and profitability

In a manufacturing environment where time is critical and quality is non-negotiable, the Osprey®25 provides the data and confidence needed to deliver flawless results, shift after shift. The system helps reduce rework, prevent customer complaints and ensure compliance with the most demanding specifications worldwide.

Learn More

Visit glassquality.com/osprey to learn more about the Osprey®25.