The Case for Warm Edge

As sustainability targets grow, warm-edge spacer systems support high performance

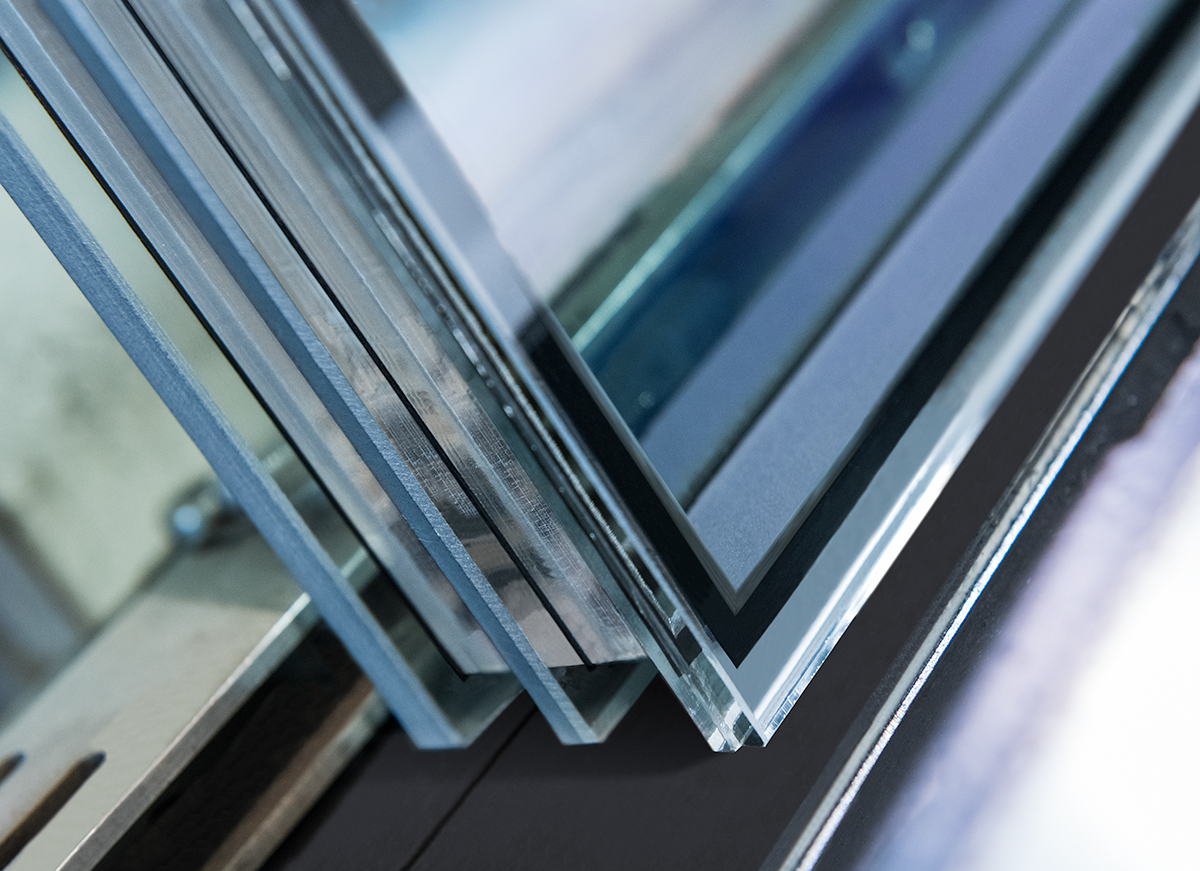

Above: Flexible warm-edge spacer bars by Edgetech (a Quanex company) used in IGUs. Photo courtesy Quanex.

Developing more sustainable building infrastructure has been one of the primary goals of the commercial glass and glazing industry for years now. More stringent energy codes continue to proliferate, driving commercial fabricators to do what’s in their power to deliver more efficient, high-performance glass. It’s an important mission—buildings are responsible for about 40% of total energy consumption in the United States, including 75% of all electricity use and 35% of the country’s total carbon emissions, according to the U.S. Department of Energy’s National Renewable Energy Laboratory. As our industry continues to advocate for high-performance glass, it’s important that we contribute to optimizing energy consumption with thermally efficient insulating glass systems.

The key to achieving our goals is applying the right technologies to ensure high performance. One of those technologies is warm-edge spacer systems, which have established themselves as a reliable option for demanding applications. For glass professionals, it’s worth staying educated on the warm-edge fundamentals—what it is, how it works and what to look for when adopting the technology.

More than thermal performance

It’s important to note that not all warm-edge spacers are the same. The term can be relatively broad and there is no industry standard that specifically defines the technology. Generally, flexible warm-edge technology offers improved IG thermal performance by reducing heat flow through the edge of the glass, leading to major improvements in thermal properties compared with metallic spacer options.

High-performance warm-edge systems can offer more than just enhanced thermal performance in end-use applications. A quality warm-edge solution can deliver a variety of other performance benefits, such as improved unit quality and consistency, long-term durability, enhanced condensation resistance, improved sightline aesthetics, reduced touch points during fabrication, acoustic benefits, and more. And warm-edge systems are highly compatible with modern automated equipment and can enable fabricators to achieve greater production efficiency on the shop floor. Following installation, a manufacturer’s IG line can become significantly more efficient while saving as much as 60% in labor costs and requirements.

Sourcing technical support

Converting from a rigid spacer application process to a flexible one involves a bit of a learning curve, just like any new technology. Rigid spacers require the fabricator to assemble many components offline into a spacer bar frame that includes the bar, joiner keys, primary sealant and desiccant, which is then applied to the glass. But flexible warm-edge technology is different; there is no spacer frame assembly process required. Flexible spacers are delivered on continuous reels and applied directly to the glass via manual or robotic applicators as needed.

That makes it important to take advantage of available technical support to help you with the transition. A good supplier of warm-edge spacer systems can provide some of that as a value-add. Again, making a switch in technology represents an opportunity to make additional improvements, and it’s an opportunity you should take advantage of.