Glass in Photovoltaics

Properties that make glass uniquely suited for use in the design and fabrication of solar cells, modules and arrays

Excerpted from NGA Glass Technical Paper FB39-25 Glass Properties Pertaining to Photovoltaic Applications, available for free download.

Among structural materials, glass has many properties that make it uniquely suited for use in the design and fabrication of solar cells, modules and arrays. All photovoltaic devices convert light energy into electrical energy through the photovoltaic effect. Common applications include in-field installations, rooftop solar, building-integrated photovoltaics, or BIPV, commercial systems, and automotive applications.

Photovoltaic applications use glass for two primary purposes: cover glass or superstrate protects the active substrate from chemical, mechanical and environmental damage, and may serve as a base for thin-film circuitry; back glass or substrate provides structural support, protection, cosmetic appeal, and may also serve as a base for thin-film circuitry.

Types of glass

The most common composition for PV applications is soda-lime glass with low iron content to increase solar and visible-light transmittance. Borosilicate glass is also used for its excellent optical quality and resistance to thermal shock, though it is more expensive and therefore limited in application. When selecting glass, consider impact resistance, mechanical strength, distortion, fall-out resistance, breakage characteristics and thermal breakage resistance.

Annealed glass offers limited mechanical protection and is suited to applications where cost is the driving factor rather than strength. Annealed glass refers to float glass without additional heat treatment. When broken, it fragments into large, dangerous shards and should not be used where breakage could cause injury or where prohibited by building codes. Heat-strengthened glass has a surface compression of 3,500 to 7,500 pounds per square inch (24 to 52 megapascals) and is approximately twice the mechanical strength of annealed glass of the same thickness.

Fully tempered glass has a minimum surface compression of 10,000 psi (69 MPa), with levels typically not exceeding 20,000 psi (140 MPa) to minimize internal stresses. It is approximately four times as strong as annealed glass and ruptures into numerous small fragments upon breaking, making it desirable where safety is a concern. Surface compression of 13,000 to 15,000 psi (90 to 100 MPa) is required to meet CE-mandated mechanical strength and fragmentation requirements (EN 12150). Fully tempered glass may undergo heat soaking to force breakage of defective units before leaving the factory, reducing risk of spontaneous field failures. Tempered glass must comply with CPSC 16 CFR 1201 standard in applications where human injury may occur in the event of breakage.

Cover glass or superstrate

The electrical output of any PV device is directly proportional to its ability to collect maximum light energy, making optically clear material such as glass ideal for cover applications. Anti-reflective coatings are commonly used to increase transmission, but chemical composition, shape and surface texture of the glass are equally important. The glass should be as flat as possible and free of deformation from heat treatment processes. Uniform thickness is a factor, since variations can decrease transmittance efficiency. Thickness itself matters because longer light travel distance increases photon loss through absorptance, though glass must be mechanically strong.

For soda-lime cover glass, optical clarity is improved by specifying low-iron composition. The glass must resist soiling and staining or accept coatings that provide low-maintenance or anti-reflective properties. Different PV technologies have different requirements depending on their efficiency at different wavelengths. The glass must exhibit a wide “bandpass” ability to provide a high transmittance at all wavelengths. Sometimes small prism patterns are imprinted on the surface to gather and focus more light energy. This patterned, cast or rolled glass typically has the pattern on the #2 surface to minimize dirt buildup that diminishes module efficiency.

Mechanical strength is critical for cover glass despite its relative thinness. Cover glass faces temperature extremes, wind loads, hail impacts, heavy UV exposure, cleaning agents and caustic chemicals. Laminating and framing stresses from bonding dissimilar materials can create coefficient of thermal expansion issues resulting in costly field failures. Heat-treated glass is often specified to add strength and thermal shock resistance.

Back glass or substrate

Back glass is on the module side not facing the sun, providing structural support and sometimes decorative appeal. The glass type may be annealed, heat-strengthened or fully tempered based on strength specifications, process and cost considerations. Since transmittance is unimportant, standard soda-lime float glass can be used with tints, patterns, textures or coatings for BIPV or spandrel applications. Slight curvatures can add aesthetic appeal. While optical distortion is not an issue, edge flatness is essential for efficient laminated assembly fabrication and structural integrity.

Types of PV cells

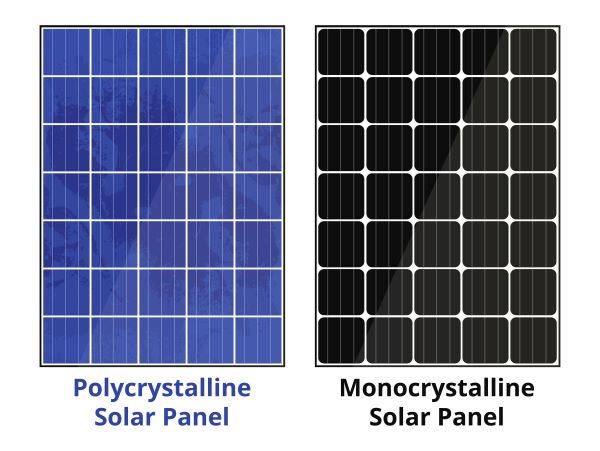

Monocrystalline silicon cells are made from single continuous crystal structures, offering high efficiency and superior performance. They are recognizable by their uniform dark appearance and rounded edges. Polycrystalline silicon cells are made from melted-together silicon crystals through a simpler, less expensive process, making them cost-effective though slightly less efficient. They have a distinctive blue hue and speckled appearance. Thin-film cells are created by depositing photovoltaic material layers onto substrates like glass, plastic or metal. Common types include amorphous silicon, cadmium telluride and copper indium gallium diselenide. They offer flexibility and lightweight properties ideal for BIPV and portable devices, with lower efficiency but lower production costs.

Concentrated PV uses large solar module arrays with focusing lenses or mirrors to maximize photons reaching active PV material, increasing output and lowering solar power costs by producing more electricity per cell than standard modules.

NGA thanks our task group volunteers for updating this resource: Julia Schimmelpenningh of Eastman|Saflex; Randy Reynolds of Glass Coatings & Concepts; Jon Griggs of Guardian Glass; Vaughn Schauss of Kuraray; Jason Fisher of Oldcastle BuildingEnvelope; Kayla Natividad and Shannon Jurca of Pilkington|NSG; Richard Wright of Richard E. Wright Associates; Nicholas Koren and Soumya Haridas of Saint-Gobain; Aaron Thompson of Viracon; and Steve Marino and Michael Hammond of Vitro Architectural Glass.