Laser Technologies

What the use of lasers has to offer the glass industry

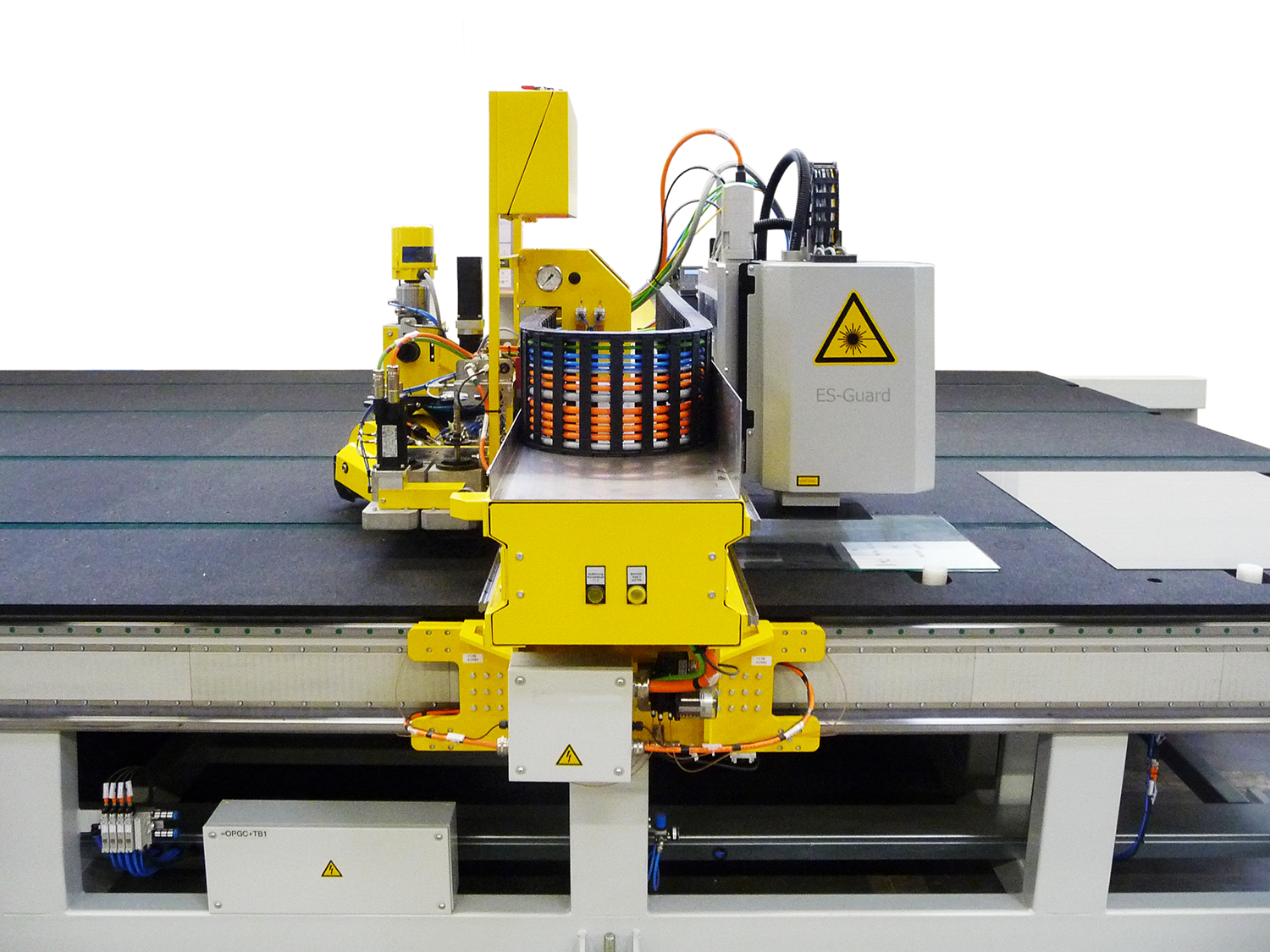

Above: Hegla uses lasers for its glass cutting machines.

Lasers have a variety of uses within the glass industry, and their applications can depend on the company and the specific services and products offered. With manufacturing applications ranging from interlayer separation to templating to field measurement, lasers offer numerous benefits to those who choose to make use of them.

Lasers for manufacturing, measurement and beyond

Hegla, a machine manufacturer, has been using lasers for 25 years now, according to Sales Support Manager Thomas Bechill. Hegla uses lasers for automatic interlayer separation on its laminated glass shape cutting machines, which involves separating laminated glass from the interlayer, as well as for hole drilling, decorative glass applications and more. To accomplish this, Helga uses its laser diode heating bulb. Prior to its laser diode heating technology, Hegla used a typical radiant heating element bulb to soften the interlayer, then stretch it enough to run a knife between the pieces to separate the interlayer. Bechill says the laser diode bulb is faster and increases the throughput of its laminated glass cutter by 20%.

Hegla also uses lasers to penetrate the coatings on exterior glass façades in commercial buildings to allow for better cell reception. “Modern, triple-insulated glass and metallic functional coatings have multiple effects: as the amount of insulation increases, [radio frequency] transparency decreases. A fine, [12-sided] pattern ensures full reception. To create it, the low-emissivity layer is removed via laser in an ultra-thin line thickness of 50 [micrometers] to enable radio waves to penetrate into the interior,” explains Bechill about the coating ablation process. “The texture generated by the laser is virtually undetectable and has no significant impact on the [insulating] value.”

Redline Templates is a technology company that brings the latest digital templating technology to jobsites. “Laser templating is used in the glass industry to create exact digital templates of spaces where glass will be installed,” says Redline Templates founder Rodney McCurdy. “The devices are used to capture precise measurements, which are then used to generate CAD files. Every measurement is captured accurately, turned into three-dimensional models, then Redline provides DXF, or Drawing Exchange Format, cut files for fabrication and PDFs for the shop to verify dimensions.”

McCurdy adds that these files are essential for fabricating glass with extreme accuracy, especially for complex or custom-shaped installations. It eliminates the need for physical templates, which he says can be cumbersome, less accurate and expensive. Redline specifically uses digital templating technology on jobsites working with glass, stone or steel, among other materials. The company specializes in two- and three-dimensional laser templating for various glass applications, including shower doors, railings and custom architectural glass.

GED Integrated Solutions manufactures insulating glass, software and vinyl fabrication equipment. GED Executive Vice President of Engineering and Research and Development Tim McGlinchy says that while GED does not use lasers directly, their machines do have the ability to import files of various shapes into its software for cutting, which utilize lasers.

GED is also the North American distributor for Sparklike, which is a laser technology that measures insulating glass units non-invasively. These devices, Sparklike Laser Integrated and Sparklike Laser Portable, can accurately measure the gas concentration and glass thickness of IG units. The company’s devices use tunable diode laser absorption spectroscopy, or TDLAS, which is a nondestructive method that measures insulating gas content in glass units through low-e coatings, as well as through triple-pane IGUs with more than one low-e surface.

Evolution and future of lasers in glass

“Initially, [lasers were] used primarily for brand and certification marking; tempering and laminated glass logos identifying the manufacturer and product compliance information in the architectural and automotive industries. However, it has evolved significantly to also provide things like barcodes, bird-friendly patterns, marks for hole drilling and more,” says Bechill.

Bechill adds that the use of lasers has also evolved from laser-etching—which would etch the glass surface, leaving a visible mark behind similar to sand blasting—to laser-printing, which fires a laser through a ceramic tape and permanently fuses the ceramic onto the glass surface. This printed mark is permanent the moment it is applied and has superior resolution to the laser etch or sandblast marking process, making it more suitable for tracking, sorting and traceability when being sorted in a factory, according to Bechill.

McCurdy and McGlinchy both say the use of lasers in software systems and scanner technology has evolved significantly over the years. “Early systems were bulky and less precise, but today’s devices are compact, faster and offer much higher accuracy. Software has also become more user-friendly, allowing for quicker processing of data. We’ve seen a shift from basic two-dimensional on-site measurements to advanced three-dimensional scanning, which is crucial for complex architectural glass projects,” says McCurdy.

“Laser measurement devices and the integration with software systems have evolved to seamlessly integrate the data into production of the glass,” says McGlinchy. “In the past, the laser measurement would measure dimensions, but the information still was transferred manually, resulting in more effort, time and, in some instances, errors in the translation from the field to the production floor.”

As low-e coatings grew in popularity, the industry needed advanced technology that permitted measurement through low-e coatings. This led to the development of Sparklike Laser devices, which can accurately measure through various coating types, according to GED Product Marketing Manager Ashraf Hussein. Hussein says that as the demand for energy-efficient buildings rises, advancements in TDLAS technology may further enhance its universal application, reinforcing its essential role in the industry.

Bechill says the capability and application base for lasers in glass has grown substantially over the past 25 years, and he fully expects this trend to continue as many of the new and improved features and functions already in development come into the market. Bechill says he cannot reveal any details regarding new products and improved features, just that Hegla is working on “quite a few that will be released at future shows and events.”

While lasers offer many advantages to the glass world, McGlinchy, McCurdy and Bechill all say that the initial investment in laser equipment and technology can be high. It also requires specialized training to operate the equipment and software effectively and, while highly accurate, technology can be affected by certain environmental conditions like direct sunlight or vibrations. However, McCurdy still stresses the overall benefits of using laser templating.

“Laser templating is not just about accuracy; it’s about elevating the standard of quality and efficiency in the glass industry. It provides fabricators and installers the ability to confidently tackle projects that used to seem daunting, knowing their measurements are exact,” says McCurdy. “Whether purchasing a machine in-house, or using a service like ours, this technology is a game-changer for reducing costly errors and delivering exceptional results to clients.”