LEED v5: MR Credits Close Up

How to get the most out of the updated rating systems

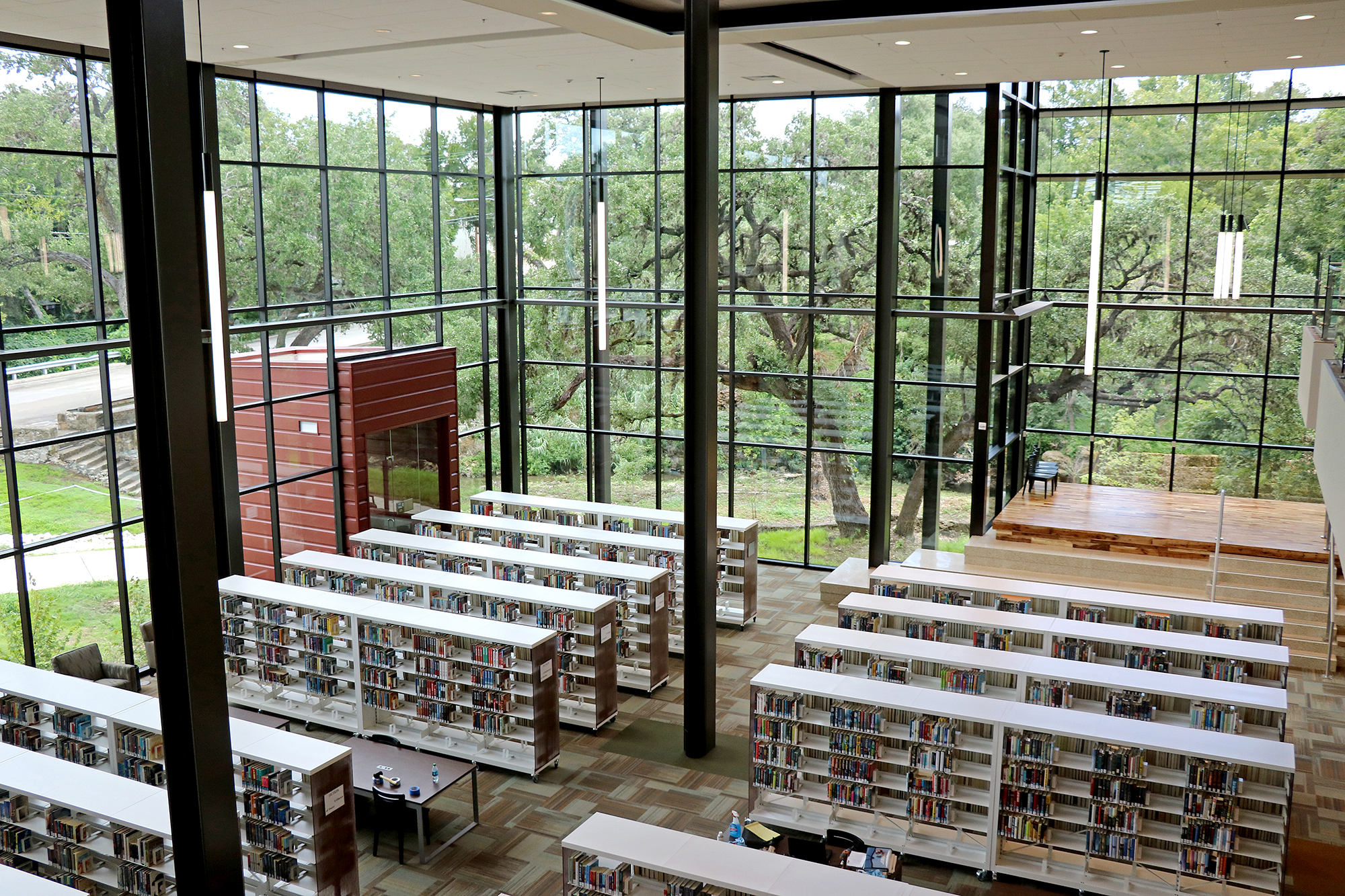

The Seguin Public Library in Seguin, Texas, is a modern, two-level building providing educational, informational and recreational resources. Tubelite supplied the high-performance curtain wall and entrance systems, which contributes to the building's sustainable, energy-efficient design and its Leadership in Energy and Environmental Design (LEED) Gold certification. Photo courtesy Tubelite and the Seguin Gazette.

As more projects are referencing the U.S. Green Building Council's Leadership in Energy and Environmental Design, or LEED v5, rating system, let’s review the updated Materials and Resources credits and the role of aluminum fenestration and framing. See my previous blog — A Look at LEED v5 and What It Means for Our Industry — for a few quick takeaways on changes in this new version.

Decarbonization prerequisite, MRp2

Quantify and Assess Embodied Carbon is a new prerequisite for the MR category. It requires that building materials are assessed on their embodied carbon, as measured using global warming potential, or GWP.

With this prerequisite, factors like the framing material's recycled content, the source of the primary aluminum billet and the framing-to-glass ratio gain importance when selecting and specifying fenestration products.

Low emissions credit, MRc3

In LEED v5, the Low-Emitting Materials credit moved to the MR category from the Indoor Environmental Quality (EQ) category. Most fenestration is not affected by these changes because high-quality manufacturers factory-finish their framing and products. This means the architectural painted coatings or anodized finishes are applied off-site under quality-controlled conditions.

When the finished aluminum material and products arrive at the jobsite, there is no health-related or air quality concerns due to off-gassing. The finished products are installed at exterior of the building and beyond the vapor barrier, further making this a non-issue with respect to the revised MRc3 credit.

Your fenestration, framing and finishing partner can provide supporting documentation for material transparency. As examples:

-

Anodized finishes contain no volatile organic components, or VOCs, which may be supported with documentation such as Declare Label as Living Building Challenge Red List Free.

-

Painted finishes also can be applied with environmentally responsible practices, such as using a 100% air capture system to safely destroy the VOCs with a regenerative thermal oxidizer.

-

Adhesives and sealants also should be reviewed to ensure compatibility and compliance.

Selection and procurement, MRc4

The LEED v5 MR’s Building Product Selection and Procurement credit introduces a new multi-attribute scoring system for products and reflects a newly combined group of credits. Previously, the four separate MR credits were:

-

Building Life-Cycle Impact Reduction;

-

Environmental Product Declarations, or EPDs;

-

Sourcing of Raw Materials; and

-

Material Ingredients.

The credit consolidation simplifies and expands the MR category to better fit with the overall LEED v5 project goals.

MRc4 can award up to five credit points. Based on the following calculation for fenestration and framing systems, this could include:

Product A (e.g. storefront) multi-attribute score x value

+ Product B (e.g. entrances) multi-attribute score x value

+ Product C (e.g. curtain wall) multi-attribute score x value

= Products’ multi-attribute subtotal x 100

÷ Total value of all products in the product category

= multi-attribute adjusted value of a product category

Consider these additional credit opportunities:

-

Remember to choose products with available documentation such as health product declarations, EPDs and Declare labels. The best case is when they have all of these as an EPD will only apply to one impact area.

-

Make sure a project’s multiple products—storefront, curtain wall, windows, doors—all have the required documents, and they are complete and compatible.

-

Wherever possible, use secondary or recycled material. Recyclability also is of key importance to the MRc5 credit, Construction and Demolition Waste Diversion.

-

Consider purchasing locally or as close to the job site as possible. Products sourced within 100 miles of the project site are valued at 200% of their base cost.

For project-specific assistance with your LEED v5 questions, contact your manufacturing partner.