Appearance of IGU Edges at the Time of Fabrication

Excerpted from NGA Glass Technical Paper FB27-15 Considerations for the Appearance of Insulating Glass Unit Edge at the Time of Fabrication

Excerpted from NGA Glass Technical Paper FB27-15 Considerations for the Appearance of Insulating Glass Unit Edge at the Time of Fabrication. For full details, download the complete document for free.

The appearance of vision and spandrel insulating glass unit edges is a function of the materials and the fabrication process. The following considerations are not intended to address changes that may occur over time after fabrication, including, but not limited to, effects due to glazing system design, shipping, handling, storage conditions or installation.

Glass quality

There are different viewing conditions and quality criteria for the glass outer area compared to the central viewing area of the IGU that may also vary depending on glass type. Non-uniformities may be acceptable if they are within the size and frequency criteria specified in the relevant ASTM International specifications: ASTM C1036 for annealed uncoated glass, ASTM C1048 for heat-treated glass, ASTM C1172 for laminated glass and ASTM C1376 for coated glass.

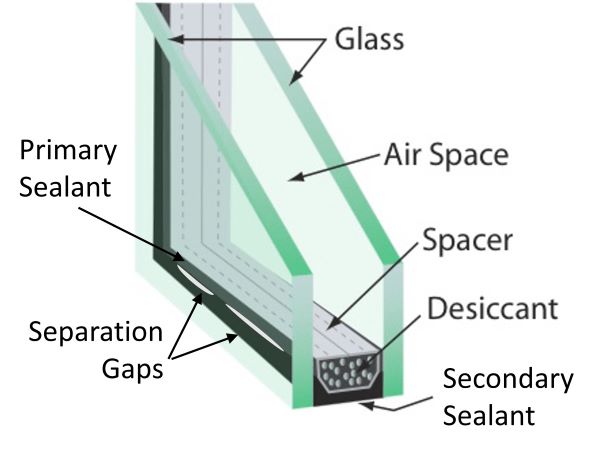

IGU spacer

The top of the spacer and a portion of the spacer side may be visible under certain viewing conditions. Different spacer types could be used on the same project. In addition, corner construction may vary in appearance depending on spacer type. This may result in an acceptable visual difference in the corner appearance. Variations in spacer color from IGU to IGU may exist due to inherent color variations from lot to lot in spacer finish, glass color, thickness and coatings.

In structural silicone glazing applications where IGU edges will be exposed to viewing, it is advisable to use a dark colored spacer. This may avoid visibility of the spacer if not fully covered by the edge sealants.

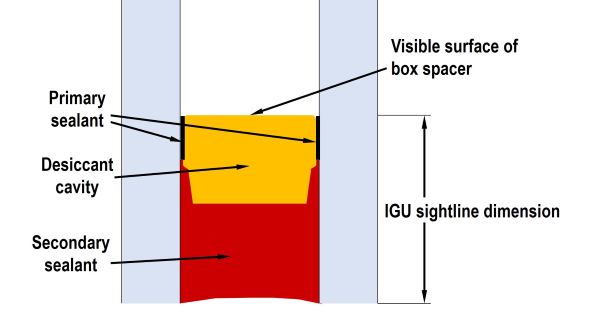

IGU primary sealant

For primary sealants that are mechanically applied to a spacer, the primary IGU sealant may extend beyond the IGU sightline into the IGU vision area (Figures 1 and 2). The extrusion rate of the primary sealant may vary, causing variation in its appearance. The placement of the spacer may also contribute to primary sealant non-uniformity when the spacer is pressed to the glass in the fabrication process. Selecting a spacer of similar color to the IGU sealants may minimize objections related to dissimilar colors.

For primary sealants that are applied manually, the primary sealant should be continuous (no voids). The edges of primary sealants may be even with, above or below the top/interior visible spacer surface. Primary sealant application to the spacer may result in variations in the primary sealant position at locations, including but not limited to, desiccant fill hole locations and corners. Such variations are acceptable.

Primary sealant infringement

Primary sealant infringement within the as-fabricated IGU should not exceed ⅛ inch (3.2 millimeters) beyond the IGU sightline dimension anywhere along the perimeter except within 1 inch (25.4 mm) of the corner, where the primary sealant infringement may exceed ⅛ inch (3.2 mm).

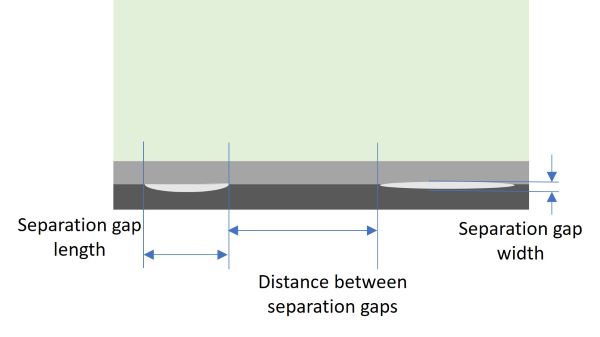

IGU secondary sealant

Typically, there is a color difference between the primary and secondary sealants. This is useful for the fabricator in performing quality checks (identification of voids and skips, etc.). The secondary sealant should be continuous, as voids in the secondary sealant may impact the performance of the unit.

Small separation gaps may exist between the primary and secondary sealants. A separation gap is the visible gap between the primary and secondary sealant where the spacer surface is visible when viewed perpendicular to the glass surface (Figure 2). The separation gap width shall not exceed ¹⁄₁₆ inch (1.6 mm), except within 1 inch (25.4 mm) of the IGU corner where the separation gap widths may be larger. The separation gap area (overall length by maximum width) shall not exceed ¼ inch square (40.3 mm square). Any two gaps along an IGU edge shall be separated by a minimum of 18 inches (457 mm).

Coated glass visual effects

Edge deletion. Coated glass manufacturers have determined removal of the coating around the perimeter (edge deletion) is necessary for certain glass coatings. Due to the multi-layer nature of these coatings and/or the coating removal process, the edge deleted area may vary in uniformity of color, width, and degree of removal.

Edge deletion is typically targeted to end within the primary sealant.

The edge deletion may extend past the IGU sightline dimension up to ⅛ inch (3.2 mm), which could result in visible edge deletion in the vision area. Contact your fabricator for specific guidelines associated with the spacer system placement and tolerances. Though primary sealant color differences may be readily visible, they should not be the cause for rejection. Viewing of mock-ups is strongly recommended.

Other visual IGU edge effectsThe apparent color of the IGU edge may vary due to factors, including but not limited to, glass substrate color, sealant color, glass thickness, applied coatings, silkscreened patterns, use of patterned or etched glass, viewing angle and lighting conditions.

The National Glass Association thanks our task group volunteers for developing this resource: Aaron Thompson, Task Group Chair, Viracon; Jon Griggs, Guardian Glass; Michael Speicher, H.B. Fuller; Melissa Szotkowski, Linel; Jason Fisher, Oldcastle BuildingEnvelope; Rick Wright, Richard E. Wright Associates; John Mayfield, Tremco Sealants; Robert Carlson, Tristar Glass; DJ Weil, Trulite Glass & Aluminum Solutions; David Cooper, Vacuum Glass LLC; and Steve Marino, Vitro Architectural Glass.