40 Years in the Florida Sun

How silicone sealants stand the test of time

When it comes to glazing systems, the long-term performance of sealants is much more than a simple design consideration—it’s a critical factor in building safety, durability and energy efficiency. That’s why Momentive launched one of the longest-running studies of glass sealant durability ever undertaken: a 40-year outdoor weathering test at the world-class Atlas Weathering Test Site in Florida.

This study tested how silicone glazing sealants performed across four decades of wear and tear, and the results suggest that silicone sealants offer significant durability over the long term.

Why long-term testing matters

Glazing sealants must endure constant exposure to harsh environmental elements, including UV rays, humidity, extreme temperature fluctuations and mechanical movement. Over time, these forces can degrade sealants, not only weakening the joints, but compromising the performance of the entire system.

To accurately assess the longevity and durability of sealants, Momentive’s study tested them in a demanding outdoor environment. The Atlas site in Florida, with its high heat, humidity and ultraviolet radiation, simulates the long-term challenges faced by sealants on buildings worldwide.

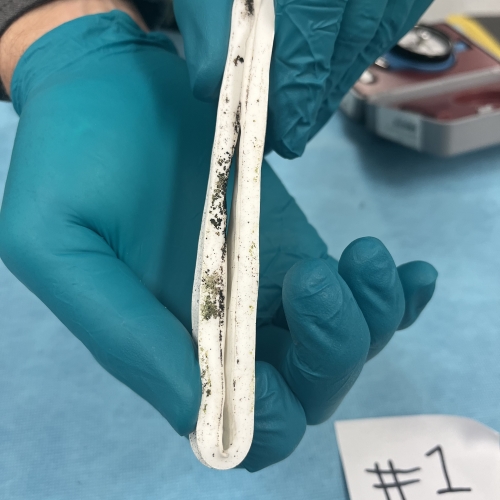

The test setup involved mounting glass and painted aluminum panels in outdoor racks angled at 45° facing south. Researchers analyzed multiple sealant formulations at regular intervals—22, 30 and 40 years—focusing on key performance indicators such as adhesion, cohesion, elasticity, hardness and surface appearance.

Silicone’s endurance: Four decades of evidence

Silicone’s endurance: Four decades of evidence

After 40 years of continuous exposure, the results were definitive: silicone sealants outperformed polyurethane and acrylic in nearly every category.

Durability and appearance. Silicones retained their original form and surface quality with minimal cracking or discoloration.

Adhesion and cohesion. A critical insight from the study was the distinction between adhesive and cohesive failure:

- Adhesive failure (sealant separates from the substrate) can lead to leaks, loss of insulation, and structural vulnerabilities.

- Cohesive failure (sealant breaks within itself) is less damaging if the bond to the substrate remains intact.

Silicone sealants maintained excellent adhesion to glass and metal substrates. Silicone’s strong adhesive bond ensured continued protection even as the building materials moved or expanded.

Elastic recovery and flexibility. One of the most impressive characteristics of silicone sealants was their near-instantaneous 100% elastic recovery—what this means is that the material returned to its original shape immediately after stress.

Acetoxy versus alkoxy: A deeper look

Within the category of silicone sealants, the study compared two primary cure types: acetoxy and alkoxy.

Acetoxy silicone sealants. These demonstrated the highest level of durability, with exceptional resistance to environmental aging. However, they release acetic acid during curing, which may not be compatible with specific substrates such as metals that are prone to corrosion.

Alkoxy silicone sealants. These release alcohol rather than acid during cure, making them suitable for a broader range of materials. While they showed more degradation than acetoxy after 40 years, they offered superior flexibility and substrate compatibility, particularly in the first 30 years of the test.

In many applications, alkoxy silicone proved to be the best of both worlds, offering safety, flexibility, and long-term resilience.

Conclusion: Building confidence with silicone

Momentive’s 40-Year Test is one of the most extensive and rigorous evaluations of glass sealant chemistry ever conducted. The data confirms what architects, specifiers and glazing contractors have observed in the field: silicone sealants deliver reliable longevity, safety and value.

Whether you're designing for high-rise façades, structural glazing or weatherproofing systems, silicone offers outstanding performance in adhesion, flexibility and resistance to environmental stress. As building lifespans extend longer and expectations around sustainability increase, selecting the right sealant is more crucial than ever.

With four decades of data to support it, the case for silicone is clear.

Test Disclaimer: Performance results will vary depending upon a number of process-related factors. Prospective customers should rely solely upon their own evaluative techniques to determine what processing parameters are attainable and optimal to their specific needs.