Heat Soak Testing of Tempered Glass

Reducing the risk of a spontaneous break

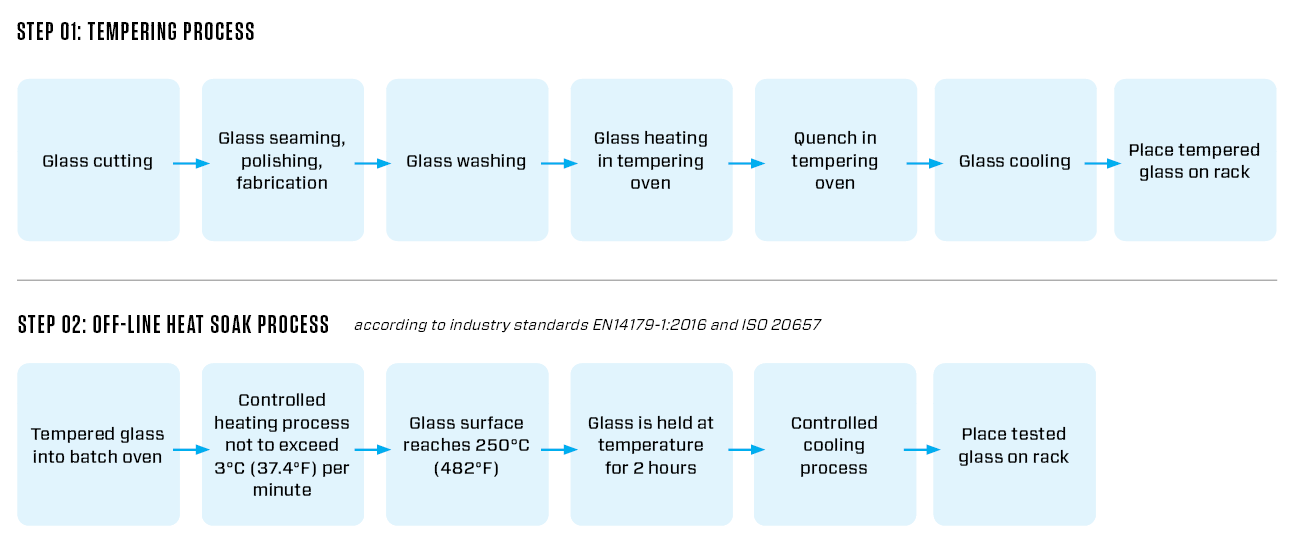

Above: According to EN14179-1:2016 and ISO 20657, the oven must be heated so that the glass temperature itself reaches 260°C (500°F) +/- 10° and is maintained through the soak phase.

Excerpted from NGA Glass Technical Paper FB56-18 (2024) Heat Soaking Testing of Tempered Glass for Architectural Applications, available to download.

Fully tempered glass used in architectural applications may infrequently spontaneously break for a variety of reasons, including, but not limited to, unperceivable imperfections or inclusions in the glass substrate. During the tempering process, the glass is heated and rapidly cooled. Most inclusions are stable; however, during the rapid quenching process of fully tempered glass, some unstable inclusions can be trapped in the tension region. These unstable inclusions, most notably nickel sulfide, or NiS, can cause spontaneous breakage if their physical form changes due to heating and cooling once installed.

The purpose of a heat soak test is to reduce the risk of spontaneous breakage in the field by influencing the NiS inclusion to break the glass during the test. It is important to remember that a heat soak test will reduce the risk but will not completely eliminate the potential of a spontaneous break due to a NiS inclusion. There are a multitude of variables that could affect if a NiS inclusion will be present in the glass during the manufacturing process, and if a NiS inclusion will cause the glass to spontaneously break. Consult with the fabricator for heat soaking benefits for your specific project.

Glass type

Heat soak testing may be done on any fully tempered architectural glass including, but not limited to, clear, tinted, low-iron, patterned and low-emissivity coated glass. It does not impact visual or performance characteristics of the glass passing the test. Reference ASTM C1036 Standard Specification for Flat Glass and C1376 Standard Specification for Pyrolytic and Vacuum Deposition Coatings on Flat Glass for more information on glass types and properties. Heat soak testing is only applicable to fully tempered glass, not to heat strengthened or annealed glass.

Laminated glass may be comprised of glass layers that are fully tempered. The heat soak testing of glass layers that are to be used in the construction of laminated glass units is typically not necessary. Interlayers can be designed to contain broken glass pieces should a spontaneous breakage to one or more of the laminated glass layers occur.

To reduce the possibility of spontaneous breakage due to NiS inclusions and preclude the need for heat soak testing, heat-strengthened glass may be utilized where heat-treated glass is being considered. However, tempered glass must be selected when necessary to comply with building codes, meet design loads and minimize thermal stress breakage.

Effect of heat soak testing on surface compression

There is currently no North American standard for heat soak testing. Some companies in North America perform heat soak testing in accordance with EN 14179-1:2016 Glass in Building—Heat Soaked Thermally Toughened Soda Lime Silicate Safety Glass or ISO 20657 Glass in Building—Heat Soaked Tempered Soda Lime Silicate Safety Glass. These standards are equivalent and have specific instructions for heat soak testing. When the heat soak test is performed as specified, there is typically no effect on the surface compression of the tempered glass.

Statistical heat soak versus 100% heat soak

There is no consensus on using a statistical sampling approach (not all lites tested). The European EN 14179-1:2016 and ISO 20657 standards require all lites to be heat soaked.

Heat soak testing process

The process of heat soak testing tempered glass is defined in EN14179-1:2016 and ISO 20657. Heat soak testing subjects the fully tempered glass to specific temperatures for a fixed amount of time through an additional heating step to accelerate glass breakage caused by potentially harmful NiS inclusions in the glass. Any breakage that occurs during the heat soak test will reduce spontaneous glass breakage in the field due to NiS inclusions. The off-line process is a batch process in which fully tempered glass is heat soak tested in an oven at some time after the tempering process.

Effect on post-temperable low-e coatings

The temperatures that the glass is subjected to during heat soak testing are low compared to the temperatures used for heat-treating. However, the coated glass supplier should be contacted for specific guidance when coated product is being heat soak tested.

Effect on iridescence

When the EN14179-1:2016 and ISO 20657 heat soak procedure is followed, the glass is allowed to cool to ambient conditions without the assistance of fans or blowers. There should be no effect on iridescence. Reference EN14179-1:2016 and ISO 20657 for more information.

Project cost and schedule implications

The heat soak process is a batch process with limited capacity that takes several hours to complete and exposes fully tempered glass to an additional heating operation and additional handling. Specifying heat-soaked tempered glass requires additional processing time for the fabricator since it involves an additional process step. Ensure that there is ample time built into the overall production schedule to accommodate the required processing time; this may also impact the project’s construction schedule. To evaluate the cost-benefit of heat-soak testing, the project design professional should consider all factors in the analysis, including, but not limited to, the volume of tempered glass, the glass construction, the consequences of glass breakage within the glazing system, etc.

Thank You to Our Volunteer Task Group

The National Glass Association thanks its task group volunteers for developing this resource: Gin Benner and Adam Mitchell, Agnora Inc.; Jon Griggs, Guardian Glass LLC; Jim Gulnick, McGrory Glass; Rick Wright, Richard E. Wright Associates; Rob Carlson, TriStar Glass Inc.; Gady Ginzburg, Vibrantz Technologies; Aaron Thompson and Chuck Wencl, Viracon; Steve Marino, Vitro Architectural Glass; and Matt Kamper, Woodbridge Glass Inc.